Webinar: The Science Behind CleanTech® - How CleanTech Works

This webinar covers everything you need to know about CleanTech® automatic hand washer systems

Watch the full recording below:

Have a question? Submit it here.

This webinar covers everything you need to know about CleanTech® automatic hand washer systems including:

- What is CleanTech®?

- How does CleanTech® work?

- How effective is CleanTech® ?

- How does CleanTech® fit into my hygiene zone?

At the end of the webinar there was an open Q&A session with Paul Barnhill, Chief Technology Officer where people asked him any questions about CleanTech® automatic hand washer systems.

At the end of our webinar, we had an extensive Q&A session and wanted to relay those questions and answers into more digestible content. If you have further questions please contact us!

CleanTech® Efficacy Questions:

A 20 second hand wash is recommended by agencies to be effective. How can CleanTech® automatic hand washer stations wash hands in 12 seconds as effectively as a manual wash that takes 20-30 seconds?

When comparing manual to automated handwashing the biggest difference is the human behavior, every time someone washes their hands they do it differently. Most people really don’t rub their hands together and really work up a lather, getting all the parts of the hands efficiently. Some people use too much soap, others not enough. Many handwashing sinks on the market have water flow too low to effectively flush the pathogens off the skin.

Automation removes the human behavior issues and allows both science and engineering to take over. The CleanTech® automatic hand washer has 40 nozzles (20 per hand) that are placed in such a way that 100% of the hand is covered. There are 8 nozzles at the wrist that direct all the water downward to prevent splashing. The next group of nozzles are designed in a helical pattern with both pitch and roll to force pathogens down and off your hand. The last 4 nozzles are directed at the fingertips. The cylinder turns around your hand 23 times in 12 seconds allowing the spraying nozzles to get in to all the cracks and crevasses of the skin with both the soapy water (6 seconds) and then a potable water rinse (6 seconds) pulling all the pathogens off the hand like a tornado. This spray pattern in combination with our proprietary hygiene solution chemistry are specially designed to work with the correct volume of water for more than 99.9% of pathogen removal. Each hand wash event is identical, thus removing the human variable and 100% of the water used in Meritech automated handwashing system is used to wash the hands, thus zero waste.

Even though the time is shorter it was done by leveraging engineering, science, & chemistry to work together to create the most effective and fastest hand wash. Check out these clinical studies looking at the efficacy of CleanTech®.

How does CleanTech® replace the scrubbing action of a manual hand wash?

We're replacing that scrubbing action or that friction of rubbing two hands together during a manual handwash with 40 jet nozzles, 20 per hand, that are designed in an optimal pattern to be able to remove pathogens. As the cylinder rotates around the hand the jets spray onto the hand and get into the cracks and crevices of the hand to remove the pathogens. See CleanTech® in action here.

Does CleanTech® wash the fingers and fingernails?

CleanTech® does wash the fingers, there's actually 4 nozzles per hand that are a higher velocity of water spray to get all the pathogens off of our fingertips. To get debris under the fingernails a brush should be used, in food environments especially fingernails should be trimmed short to prevent build up of soils under the fingernails so they can easily be cleaned and freed of pathogens. See CleanTech® in action here.

Does CleanTech® wash AND sanitize the hands?

Yes it does. We are washing and sanitizing the hands all in one 12-second cycle eliminating the use of hand sanitizers after a manual handwashing process.

Can CleanTech® be used with heavy soils?

When you're dealing with heavy soils, ideally you should be using a disposable glove. That way when the glove comes off, it goes into a waste bin and those debris don't end up in the sink and promote pathogen growth. If you're not using gloves, use a paper towel to get those debris into a waste bin, so they don't end up in the sink. Then once hands are free of excess debris, the CleanTech® system can be used to remove those 99.9% of pathogens.

CleanTech® Mechanics Questions:

How much water is used during one 12-second cycle?

6/10ths of a gallon is used in each wash cycle. An important note to make is that when washing your hands manually about 60% of the water used never even touches the hands. With CleanTech® 100% of the water used touches your hand and assists in pathogen removal.

How is no water wasted using CleanTech®?

With traditional manual handwashing methods, much of the water used actually goes down the drain as you're scrubbing your hands for the proper length of time. With a CleanTech® system 100% of the water used touches the hands, so zero water is wasted.

Can CleanTech® cycle time be increased for my facility?

While CleanTech® cycle time can be adjusted, we have found that with our 12-second cycle stations remove more than 99.9% of harmful pathogens, therefore we do not see benefit from a longer cycle.

Does the CleanTech® system heat the water?

No, the systems do not heat the water so you'll have to have a hot water source for the system. However, all service engineers are trained to identify water temperature concerns, address these, and give recommendations on the best practices to maintain the ideal water temperature. You can contact them here.

How does the handwashing counters work (master and resettable)?

We're really counting every single hygiene event with the CleanTech® system. The master counter gives you a collective number of hygiene events performed for the specific machine. The optional resettable counter brings the counter back to zero with a simple push of a button to give hygiene managers a resettable data point to check that employees are following hygiene SSOPs without having to police the behavior and have that data to adapt hygiene protocols appropriately.

What are the basic utility requirements for the CleanTech®

To use CleanTech®, you'll need a hot water source, a cold water source and standard one and half inch drain and a standard power outlet. If you have the wetted boot dip enhancement, you'll need the floor drain for that. If you do not have a floor drain, we can help with alternative draining options.

Can the CleanTech® system be adapted for international utilities?

We actually provide an international adaptor kit with each CleanTech® system that will adapt for the plumbing requirements. If you're in another country we will automatically adapt the system to work with international utilities. Internally the systems are running at 12 volt DC so a very low voltage and in that we have a universal power supply that converts any voltage down to that 12 volt DC.

How do you train staff to use a CleanTech® system and how is that different than teaching manual handwashing?

One of the key aspects of using a CleanTech® system versus a traditional sink is really the simplistic method of training. Training with a CleanTech® really only takes about 12-seconds, the length of an automated handwash cycle. One of the pitfalls with traditional hand hygiene is the constant reassurance that you have to give. The teaching and training and retraining as well as the challenge of doing that in multiple languages. With CleanTech® systems it's 100% visual so it's very easy to follow. You just stand there, put your hands in the system and in 12-seconds you have clean hands!

What is the cost per hand wash using a CleanTech® system?

The cost per hand wash varies between $0.05 - $0.09 per hand wash depending on additional features or enhancements you may include and whether you purchase a service agreement for routine maintenance and calibration.

Hygiene Solutions for CleanTech® Questions:

How does the self-cleaning feature work in the CleanTech® system?

Meritech has developed a proprietary SelfClean solution that is specifically designed to sanitize the interior of our high-throughput industrial CleanTech® models. This high pH surface cleaner automatically runs throughout the system, for 20 seconds, three times per day or when the system power is turned on to provide low-maintenance prevention for the growth of dangerous pathogens in the system and facility. The solution will actually run throughout the entire plumbing tree from the solutions injection point all the way through the cylinders and down through the system drain to shock and kill any pathogens and prevent mineral buildup.

Why can't I use someone else's soap in the CleanTech® system?

Using someone else's soap compromises the efficacy of the CleanTech® handwashing station and your facility's hygiene. Meritech has performed over 50 efficacy studies to give you data on how effective our hygiene solutions are at removing pathogens when used in the CleanTech® handwashing stations. You will not get that same level of 99.9% pathogen removal that is backed by data with other soaps.

How many hand wash cycles does the hygiene solution provide?

For each two and half gallon container of UltraPure hygiene solution you will get approximately 1,800 hand washes. With a CleanTech 2000 and 4000 that uses the SelfClean solution during the self-cleaning cycle you may get slightly less handwashes. This is because after the self-cleaning cycle the system actually uses a bit of the UltraPure solution to make sure that there's no chance of that high PPM SelfClean solution of coming into contact with human skin.

Is the hygiene solution environmentally friendly / biodegradable?

Our hygiene solutions are a proprietary formulation that contain skin conditioners and quat-based antimicrobial sanitizing chemical proven to be very effective in removing pathogens and promoting long-term skin health while also meeting and exceeding regulatory environments. Plus, since our station minimizes water and solutions waste, it presents a better option for the environment in minimizing the 'handwashing footprint.'

CleanTech® Enhancements Questions:

Does the CleanTech® system dry hands?

Meritech recommends the use of single-use paper towels to dry hands. However, we do have an air curtain enhancement that is compatible with our 500EZ, 2000S and 4000S models that at the end of every wash cycle, a curtain of compressed air blows onto the hands to partially dry them, reducing paper towel waste. It is ideal for companies seeking a “greener” footprint while maintaining sanitary standards that other dryers can’t match.

General Hand Hygiene Questions:

Do you need to wash hands if you are using gloves?

Yes! Wearing gloves does not remove the need for handwashing. A hand hygiene event should happen prior to donning gloves. Gloves can have unseen defects or can be torn during use, providing a point of contact for the skin. In addition, bacteria can multiply rapidly in moist environments underneath gloves. We should also note that just like your skin, gloved hands can pick up germs so it is important to perform an additional hand hygiene event after donning gloves.

Why would you want to remove pathogens when you could kill them?

The skin is your largest organ, and the things used to kill harmful pathogens will also damage if you do not take proper care of your skin. The action of removing pathogens with soap and water is much more forgiving to your hands when compared to killing pathogens with alcohol-based sanitizers. Read more on the topic of skin health in this post.

How does water temperature affect handwash efficacy?

Temperature does not affect the efficacy of handwashing events. The water temperature human hands can handle maxes out at around 105º F which the vast majority of pathogens can survive. Where water temperature comes into play is with compliance. People are more likely to wash their hands well and for the recommended amount of time if the water is comfortable.

Are air hand dryers the recommended method for drying after a hand hygiene event?

No, Meritech recommends single-use paper towels. The reason air dryers are not recommended, particularly when it comes to COVID-19 which is spread through micro-droplets, is if someone is coughing or sneezing in the area, a high-velocity dryer will pick up that droplet and deposit it onto hands that were just washed.

We referenced several resources throughout the webinar, please find these below:

- Employee Hygiene Toolbox

- CleanTech® Efficacy Studies

- Hand Hygiene Comparison Guide

- CleanTech Handwashing Stations Overview Video

- Hygienic Zoning Video

Paul: Hi everyone and thank you for joining us today for our webinar about CleanTech® Systems. My name is Paul Barnhill, I'm the Chief Technology Officer and hygiene expert here at Meritech. For the last three decades, I really focused on one thing: how do we improve and automize and automatically maintain technologies to improve hygiene?

So let's go ahead and jump into our webinar. We're going to really talk about the CleanTech® systems today, and let's go through a quick agenda of what we're going to do

Today, we're going to give you a brief overview of Meritech and what we do. I'm going to explain in-depth how theCleanTech® Systems work mechanically, the science and efficacy behind the handwashing stations, the markets the CleanTech® Systems are currently being used in, and finally, an open Q&A session. Please note, we will be providing a lot of the resource material from this webinar that you can download or any questions we don't get to will be answered in our blog.

Meritech is headquartered in Golden, Colorado and was founded in Colorado 30 years ago. All our hygiene stations and solutions are manufactured in the United States. We have a dedicated team of hygiene experts throughout the United States. Meritech also has key partnerships in our international markets. As experts in human hygiene, we've focused on creating innovative technologies that address the pitfalls in human behavior to improve hygiene and throughput for many organizations. We have a simple mission as a company, make the world a healthier and safer place by redefining human hygiene. Our vision, overcome the variability of human behavior to ensure effective hygiene by providing a standardized, clinically validated and documentable washing and sanitizing process, regardless of user language or skill level. This really defines the CleanTech® hand washing experience, and together we can transform hygiene for a healthier, safer, world.

Meritech has three distinct categories of technologies we offer: fully automated handwashing stations with optional enhancements to address all footwear hygiene, a full line of high throughput, footwear and boot scrubbing systems for all types of debris that is encountered in food plants and our solutions line that is specifically designed to work in conjunction with all the Meritech hand and footwear products. Today we're specifically covering the CleanTech® line of stations.

So what are the problems that face all businesses when it comes to poor hand hygiene? It really boils down to three main areas: poor human hygiene can impact others, health and safety- this is from not washing the hands properly and consistently. Harmful pathogens is another, this we know all too well with the current situations playing out before our eyes that is affecting the entire world. Most pathogens are transmitted from surfaces to hands, and then that can affect the person or other people. One of the biggest issue is human behavior and consistently and effectively washing their hands correctly every time. Every manual hand wash event is always varying from event to event and that leads to higher risk and spread of unwanted pathogens.

In a study published out of London, researchers estimate that if everyone routinely wash their hands, a million deaths a year could be prevented. In addition, a study shows that only 5% of people wash their hands properly when washing manually. Those are staggering statistics!

Between production, distribution, and normal human behaviors, hundreds of hands come in contact with products and each other. Just one pair of contaminated hands can cause an outbreak, resulting in wasted product or worse, a loss of human life. At Meritech, our mission is to save lives and prevent the spread of disease through effective employee hygiene.

So what are the pitfalls of human behavior when it comes to handwashing?

The amount of time the person washes- the human aspect of consistently washing is by far the largest variable when it comes to washing correctly. Are they focused on the time it takes to wash properly? Are they focusing or following a guide for the proper washing technique? Have the team members been properly trained and onboarded in a way they can follow proper hand washing protocols? Did they use enough soap- too much or any at all? Is the soap or solution they are using specific to the task at hand? No pun intended.

Is there a significant quantity of water need to wash away the debris and pathogens? There are many situations when using certain sinks that you don't feel as if there's enough water to wash off the suds- thus, the pathogens. Is the water the right temperature to encourage handwashing? Is the area where hand hygiene being performed, or what we call a hygiene zone, designed for consistent flow and allowing enough personal space and time for quality hand-washing events? How do you verify the hand washing is being performed properly without policing the behavior? Automation is used in so many areas of our daily lives to overcome human variables and hand hygiene is no different- and at Meritech, that is our mission.

Alright, so we just went over some of the pitfalls of human behavior when it comes to hand washing. Next, I'm going to shed a bit more color on the pros and cons of most common hand washing methods. But first I want to start a poll to see what's happening with your hand washing methods that you're using today.

Abigail, take us into the poll.

Abigail: Alright everyone, a poll should have just popped up on your screen. Please let us know what hand washing method you're using at your facility today. If you're having any problems viewing or responding to the poll, let me know in the webinar chat pane. I'm going to give everyone just a couple more seconds here to complete the poll .

Paul while we're waiting, how do you train staff to use a CleanTech® System and how is that different than teaching manual hand washing?

Paul: Well, that's actually a really really good question, Abigail. One of the key aspects of using a CleanTech® System versus a traditional sink is really the simplistic method of training. You know, training a hand hygiene event within a CleanTech® System really takes less than 12 seconds. And that's the length of a hand hygiene cycle! One of the problems or one of the pitfalls with traditional hand hygiene is really that constant reassurance you have to give of constantly teaching and training and retraining as well as the challenge of training and multiple languages, and how to do that. With the CleanTech® Systems, it's 100% visual, so it's very easy to follow and you just stand there, put your hands in the system and it just takes that 12 seconds.

Abigail: Alright, thank you, Paul.Let me share the results with everyone. It looks like everyone is mostly using manual hand washing at their facility today. Thank you for participating in the poll, Paul back to you.

Paul: Thank you, Abigail. Thank you everyone for taking the poll.

There are a few common methods, widely used to wash hands. However, each method has its own pros and cons. It really depends on what I like to call the three P's: the people, the place and the products. We'll get into that a little bit later on. There are three most common methods used today:

Manual Hand Washing Stations & Traditional Sinks

We're all familiar with traditional sinks- some may be manual or have automated faucets or a separate soap dispenser. However, sinks do have inherent disadvantages. Each hand hygiene event is relying on the behavior of the user each time. There's no data on the number of hand washes being performed. Was the right amount of soap or any used? They can also be very wasteful of water that just pours out the faucet that never touches the hand. If it's a low flow faucet, it may not have enough water volume to fully rinse away the pathogens. Increased education and reeducation on proper use for it, is always required with manual washing. One of the items I've observed over the years, I call the "splash and dash". People just wet the hands for a couple of seconds, no soap and walk away. Clearly not a proper hygiene event.

Instant Hand Sanitizers

Instant sanitizers are only capable of killing, and do not remove anything. They do not work on hands with soil and debris. When they're used, it relies on human behavior to use the correct amount in the hands and it needs to stay unevaporated for a period of time to have the opportunity to kill the pathogens. It leaves an emollient layer behind that can be uncomfortable and builds up in time. It also doesn't kill all pathogens like Clostridium, difficile, or Norovirus. To break the cycle of hand sanitizer and emollient layer buildup, you must wash your hands every three to five applications of the hand sanitizer. Some less expensive sanitizers do not have enough alcohol in them to be effective quickly.

CleanTech® Fully Automatic Hand Washing Systems

The third option is fully automated hand washing like CleanTech® automatic hand washing stastions made by Meritech. Each hand hygiene event is performed the exact same way for every user. Training and onboarding are easier as it's all visual and easy to use, regardless of language or skill. It's a clinically validated technology that's proven to remove more than 99.9% of harmful pathogens from hands with each 12 second cycle. Plus, it's an eco-friendly hand hygiene solution, wasting no water or solution.

Make certain, you fully understand the challenges in your facility. So the correct methods are effective and meet the need of the business regulatory requirements and eliminating both pathogens and human risk.

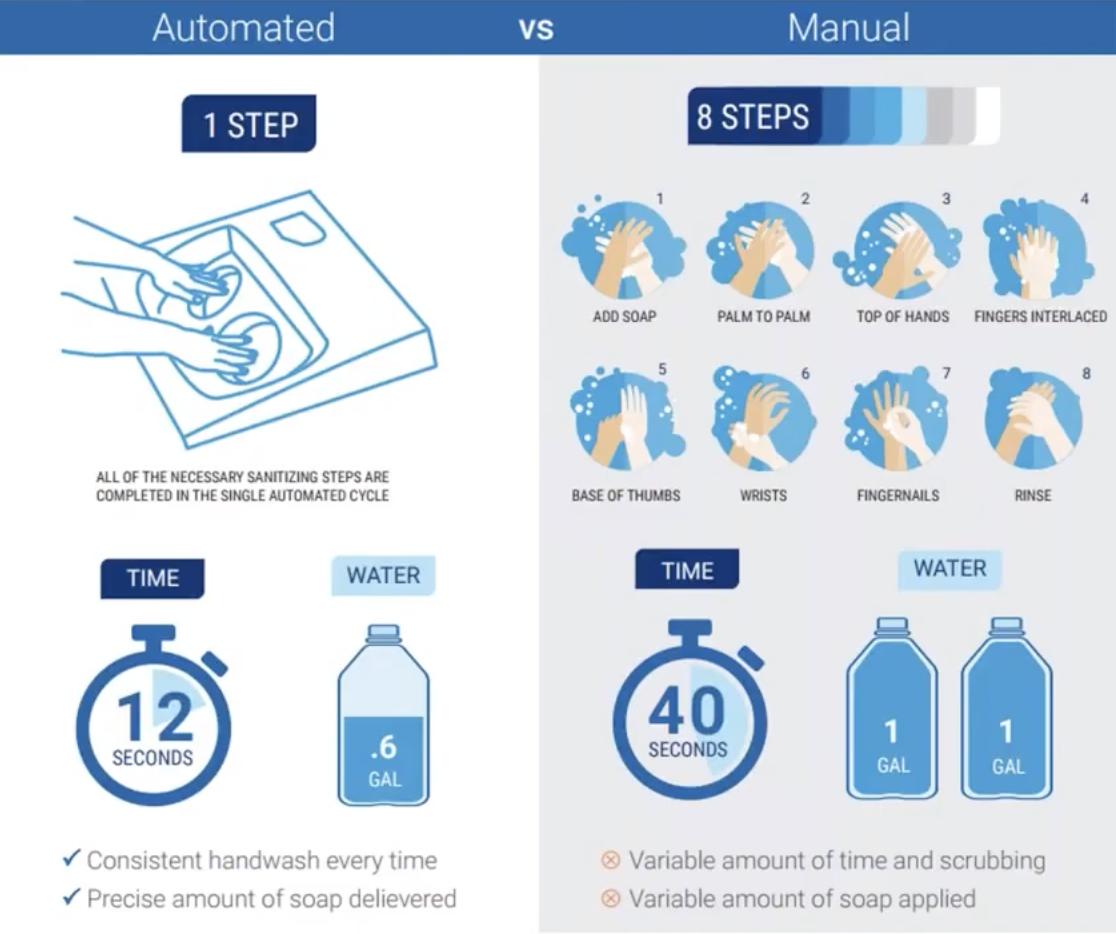

As you can see right now, we have a quick pictogram that's really separating the two different methodologies.

We have automated on one side, we have manual on the other. With the automation, it's really a one-step process. When you're looking at the manual, you know, it's really about eight steps at minimum or can be up to about 12, depending on that washing technique. And you look at that, you look at the big variable there is time. CleanTech® Systems take 12 seconds to work. When you talk about 40 seconds for washing, even though a lot of people say, well, it's really about 20 seconds, but really in reality, it's really 40 seconds. When you do a pre-rinse, you do the lathering and scrubbing for that 20 seconds you do that post-rinse and that time builds up and it ends up being more along those 40 seconds. When you look at water conserving, we're using exactly six tenths of a gallon. When you look at a manual sink, you're typically right around two gallons. So it's really about being consistent versus inconsistent and water conserving versus wasting water.. And the biggest variable is time- our most valuable asset in business.

When selecting a method for your syllabi, it's important to select a process that's appropriate for your environment. In this chart is an overview detailing seven hand hygiene methods and 11 key categories that need to be evaluated when choosing the hand hygiene process. Again, this will be available as a download at the completion of this webinar.

So why is automation for hand hygiene important?

Removes inconsistencies

It removes the inconsistencies of hand washing behavior and allows automation to create and deliver a quality controlled hygiene event. It's the combination of engineering, science, and chemistry brought together in a single technology to deliver a consistent and effective handwash every time to eliminate risks.

Validatable data

One of my mantras in life is "within consistency, you can build quality". Automation achieves that and helps with creating a hygiene culture and food and health safety best practices. CleanTech® Stations deliver on all these attributes.

How Does CleanTech® Work

Now we're going to dive into how the CleanTech® Systems work to get a better understanding of what is happening in the 12 second hand-washing process.

We're going to watch a quick video to really highlight the value of the CleanTech® Automated Handwashing Stations. After the video I'll breakdown the entire CleanTech® hand washing process.

So let's go ahead and break down exactly what the CleanTech® Handwashing Systems and hygiene events is doing.

CleanTech® Stations are the world's only fully automated hand-washing systems engineered to break the human variables and make hygiene training simplistic. Food, pharma and many other industries have diverse work cultures with different hygiene requirements.

So now we're going to go ahead and describe exactly what's happening when you start a hand-washing cycle. So the first thing you see is, you know, once the photo-eye is broken, it's what we call the one and done, and the cycle begins. There's no need to move the hands around. It makes it work like you would normally have to do with a photo-eye faucet and so forth. So again, once your hands go into the system, the system automatically starts and turns on. The water comes out immediately. So all you have to do is just keep your hands in the middle of the cylinders with your fingers slightly spread and allow the station to do the work.

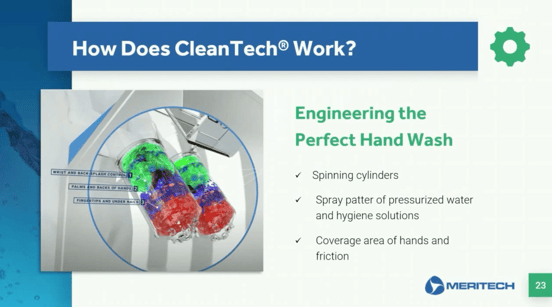

So now that you can see on this picture, we actually have in the system there's actually 40 nozzles, 20 per hand, and we've actually broken down by color that you can see on the screen right now, the three different segments of really the hand washing process that are going on in there. So what happens in there with those 20 nozzles per hand that are designated by color is you have the green zone, the blue zone, the red zone. That cylinder is also rotating around your hand 23 times in that 12 seconds, washing clean the hands. So that the first nozzles that the green color there's actually 8 nozzles at your wrist. And those eight nozzles are really blocking the water from splashing out as well as then keeping the energy of the water focused inside the cylinder.

Then you have a helical pattern, another eight nozzles in the helical that kind of go down around your hand. Now all these nozzles, these eight nozzles actually have what it's called pitch and roll to them, and what they're doing as they roll around your hand, they're wiping and pulling pathogens off your hand as it rotates down.

And lastly, we really have the business end of the nozzles. We actually have four nozzles dedicated at the tips of the fingers. This is really to address pathogens on the tips of the fingers between the fingers and so forth. One thing that's different about those nozzles is we've changed that type of knowledge internally to make sure that we have higher velocity of water. We're working a little harder because your fingertip, the skin on your fingertips is a little harder. It's a little tougher, but this is the business end of the hand. And the part that covers every bit of what we do.

So let's break down that 12 seconds of what we do. So when you put your hands in, you've broken that photo-eye beam, and the water comes on. There's actually a second of pre-rinse. Why is that important? Two reasons: one, we want to wet the hand. We want to make sure that it's able to, to get ready to receive the mixture of the anti-microbial solution and water as well as that's an opportunity in that one second blast, we actually take the opportunity to really remove any of the large pathogens, allow the anti-microbial solution to really work on the smaller, more difficult pathogens. So we're trying to optimize the pattern.

Then we give you that five seconds of washing cycle. That's where the mixture of the anti-microbial solution is mixed with water and washing and sanitizing the hand. And then finally at second six, the system immediately gets over and kicks into a rinsing portion. That's a portable water rinse and we're a hundred percent rinsing that hand.

So in the system, there are 40 patented nozzles that are doing the cleaning and getting into all the cracks and crevices of the skin and thus replacing the friction of rubbing your hands together.

CleanTech® Hygiene Solutions

Meritech in its early years decided it needed to develop its own unique solutions so that we get effective and clean and control the entire hygiene process and achieve the highest pathogen reductions in the shortest period of time. Our blend of solutions mix the correct balance of anti-microbials with detergents to get an effective PPM clean when mixed with the appropriate amount of water. We made certain our solutions were free of skin damaging effects that dyes and fragrances can have, free of triglycerides, and it was developed to be gentle on the skin, allowing more frequent washing. The CleanTech® Station cylinders have a closed loop draining system that is separate from the system's main drain. This allows for decreased risk of cross-contamination.

One of the things I want to go over a bit right now is actually talking about the general utility requirements that all the CleanTech® systems require. They do need a hot and cold water inlet, a one and a half inch drain, 110 volt electrical outlet. And if you have one of our boot dip enhancements, so this is the wetted boot dip enhancement. You'll also need a floor drain to go with that. I'm often asked how much electricity this system consumes- it's very economic. If you have a hundred people in your plant washing five times a day, your monthly electrical cost to operate a CleanTech® is just under $2 per month.

Over the years of observing tens of thousand of hand washes, one thing has been very apparent was the quantity of water used. When you look at a manual hand wash, there's an abundance of wasted water and with a manual faucet, knee, or foot pedals sink, approximately 60% of the water used never touches the hands.

Photo-eye sink faucets are a challenge challenge as well. They never seem to stay on long enough or have enough waterflow to be as effective. The CleanTech® systems use only six tenths of a gallon of water every time, and there's zero waste as 100% of the water is used to clean the hands.

CleanTech® footwear enhancements

Meritech offers many enhancements for the clean tech models, some of the more popular are those for footwear sanitation, which combines hand hygiene and footwear hygiene at the same time. Again, allowing automation of the CleanTech® system to keep the footwear hygiene station at the correct PPM and automatically recharging based on time or use. So how do the footwear hygiene products work? So we've got a couple of them shown on the screen above. We have a Wetted Boot Dip system, and we also have our Sole Clean, which is designed for low moisture environments.

Wetted Boot Dip

So the Wetted Boot Dip is designed for environments that can be wet obviously. We, make certain that the correct parts per million of a quat based product is automatically put into the pan. And typically the calibration of 800 to a 1,000 parts per million, meeting the FDA recommended guidelines. It's easily mixed by the station with a quick drain for easy cleaning, and a quick fill with a push of a button.

Sole Clean Low Moisture

Now the Sole Clean system is really used in those environments that you really want to stay dry. So what we did is we have a blended chemical, which is blended alcohol solution that is used in and evaporates really quickly. So what you do is you're standing there, it dampens the soles of the footwear again, it's an alcohol blend sanitizer it quickly evaporates. It automatically replenishes and has a quick drain for easy cleaning and quick fill with the push of a button.

Pitfalls with alternatives in footwear sanitation for food safety

The traditional methods of a doorway boot dip or door foamers, don't compare to a CleanTech® station with a footwear enhancement. With the traditional methods, someone has to remember to change the sanitizer or when they're used they step in and step out with less than a second contact time. Meritech's footwear enhancements automatically replenishes, and when someone is using the hand washer, we have 12 seconds. So that's 12 times the contact time, to allow the sanitizer to work and kill the pathogens.

Improving handwashing compliance for food safety with CleanTech®

Though, the fully automated hand washing station helps improve hygiene behavior, equally important is the user interface. This continually enforces hygiene best practices. So at the top of this, we have a countdown timer. So what that does is once you put your hands into the system immediately, it will turn on, and it will start counting down from 12 to 0. When that counter hits zero, it's a very clear indicator to your staff that they can pull out their hands- another way to note that the water will automatically shut off. On the display, it will actually let you know when the cycle is complete and when you can remove the hands. This display will also tell you when it's washing, it will also tell you when it's rinsing- all that within that 12 seconds cycle. Additionally, on the user interface is really the master compliance counter, as well as a resettable compliance counter. The advantage of the master counter is really to get a total perspective of your total hygiene events. This is the non-resettable number. Now the advantage of also the greater advantage is actually a resectable compliance monitor. What can be done with that is that you can decide when to collect data. So if you want to collect data per day, per week, or even down to per shift, you can look at various zones and see how many people, or maybe how many hygiene events are coming through a certain area so you make sure that you're meeting your goals and expectations. And it's a really good QC measure and validation point of the number of hygiene events that you're having without policing the behavior.

Also included on that are two green bars. Now you can see that you would have the one on the left which for the UltraPure solution, the one on the right is for the self-clean solution. These actually show you the level of fluid that's actually in the container, so you know when it's time to change. So when that does get low, two things are gonna happen. One is the green bars, the last two green bars, will go ahead and flash and indicate that it's empty as well as the display will tell you what solution needs to be changed out.

On the CleanTech® 2000S and 4000S models they have the self-clean feature. And let me tell you a little bit about what that is. The self-clean feature is a feature that once a day will automatically turn on and it's going to clean the system. It's going to use a surface cleaning product, a higher quat concentration that runs for about 20 seconds and it runs all the way through the cylinders, down the system and so forth to help eliminate and shock and kill any pathogens that could be in the system. When the system is cleaning itself, it will actually indicate that it's cleaning. Should someone try to use the system when that happens, immediately the system will shut off. It will tell you that it's cleaning itself and tell you to remove your hands. Once your hands have been removed the system, the self-clean cyclewould start again- the whole process only takes that 20 seconds.

How Effective is CleanTech®?

Paul: So let's talk about the efficacy of the CleanTech® systems. Early in the presentation, we mentioned our efficacy data and what studies we've performed over the last 30 years. One of those first questions were always asked is how effective the solution is against the pathogen. So let's look at this in a little broader spectrum.

So when we're talking efficacy, we're talking about the entire process- not just the station or the solution by itself, but the entire hygiene event. By combining the station and the solution and studying the science, we're able to achieve that 99.9% or greater pathogen reductions. Since 1990, Meritech has performed over 50 lab studies to test the efficacy of our automated hand washing stations and we continue to test improve and retest CleanTech® in order to provide the perfect hand wash every time in 12 seconds. The efficacy data has been performed and backed by a third party testing facility that is the leader in hygiene and topical anti-microbial testing in the country. Meritech has made this investment because we care that our customers get science-based technologies and a company that is a partner in hygiene excellence.

Alright, let's boil down the efficacy data a little bit more. So we perform pathogen specific testing. So we know what we're looking at. This way, we don't cloud the data with unknowns of maybe resident or transient pathogens. So let's talk about that really quick. So let's talk about the differences in a quick explanation of the differences of resident vs transient pathogens. Obviously resident pathogens are coming from within. You know, there's about 500 different species that live within our skin. And then we have transient pathogens. These are those pathogens that we pick up from surfaces, from possibly other people or doorknobs, buttons, so forth and so on.

The reason why we want to look at doing pathogen specific testing is, again, we don't want to cloud that data. We want to make sure that the information that we're given is correct and accurate. There's a lot of times when you're collecting that data in different methodologies, you actually may not be looking at that pathogen you want to be testing.

People need to understand what that is. All the testing that we do is in- vitro testing. So we're actually testing some live human subjects. So when we do the task, we actually put a known amount of a pathogen directly on the skin. We then measure that and create a baseline. And then after that baseline is determined, we then apply pathogen again, and then we do a hygiene event and then we measure and then we'll do it again, we'll apply more pathogen, we'll do a hygiene event and then we'll measure. We just keep doing that to get a statistical average. And actually what we're doing there is getting that variability.

Now, one of the things, when we're doing this testing, both pathogens- specific as well as again in- vitro testing is because skin is its own ecosystem and considerations that are very unique to each individual. You know, how is my hydration level compared to the next person? What is the pH of my skin compared to the next person? Even my age may have some effect in the way different pathogens are. This is why we want to give you variable in results. And when we propose data, we're talking about a mean average of that. We need to also keep in mind, skin is the largest organ. So we have to be able to protect that and make sure that whatever we're putting on it and or whatever we're removing is protecting the skin.

Again, all this testing is performed by a third-party GLP laboratory. We also follow an ASM E-1174 standard. Now what we call that is the "Glove Juice Method". That is very important because you want to make sure you're following a standard that meets a protocol, and you're collecting that data the same every time to get consistent results. Meritech has procedures for our customers to validate hand hygiene events, to help onboard systems as well as continued verification, post installation.

Learn more about our ATP Testing Guide here

One of the things that Meritech is getting ready to do in about a week is Meritech is getting ready to study the human coronavirus. And so stay tuned. We're going to do this and present the data in about three to four weeks. Once we know how the CleanTech® systems using the UltraPure solution perform when challenged with human coronavirus and how effective they are, we'll let you know.

Learn more about our efficacy date here.

I also want to point to a link on this page that is to our efficacy data. It's a full summary of the efficacy data and if you need to, you can also request one of the full detailed study. I also want to call out that a podcast where to do on hand hygiene validation. And so please, in the data that we give you, you'll see a link to that and you can listen to that podcast where we talk about hand hygiene validation.

In this chart we're showing the results of a few of our clinical studies against some of the more popular pathogens with E.coli at three log or 99.9% reduction and norovirus at four log or 99.99% reduction. The other two pathogens shown are more on the resident versus transient pathogen family, and more difficult to root, but showing extremely high reductions in pathogen load. Please keep in mind that Serratia is a pin dot shaped, and E.coli has a rod shape and Serratia is a hundred times smaller than E.coli. Both pathogens were in a E-1174 testing model.

Footwear Hygiene Efficacy Testing

When we started researching footwear hygiene, efficacy data, we didn't see a lot that had been published and/or peer reviewed. We also didn't see a consistent test methodology. Meritech developed a protocol for hygiene efficacy testing. And we're currently looking at that process for this to become an ASTM standard, which is a bigger project.

We decided the number one and number two most known for pathogens were Listeria and Salmonella. Again, we're talking about the Wetted Boot Dip and the Sole Clean Low Moisture, footwear sanitizing enhancements. So as you can see in this chart here, we're showing you both the Listeria and Salmonella what those reduction rates are. So as you can see, with Listeria we received a 96.8% reduction and Salmonella a 99.8% reduction. As you can see, we received a lower efficacy result with Listeria when challenged with SelfClean, that's what science is all about. It's really learning from the results and adjusting to achieve improved results. So we're looking at that. Could we have seen that that result was something due to maybe a misstep within the protocol? Was that something that maybe we got a miscalculation of the data or so forth? So we're looking into that and doing additional testing to be able to figure out exactly why we're not able to get a higher pathogen reduction.

If we came out of the gate every time, always with perfect results, I would still personally question "why?" We want to make sure that we validate our data. We want to make sure that we understand the science behind it. And what is the mortality rate of that pathogen and figure out what is the best way in the shortest period of time that we can kill that pathogen, especially when it comes to hard surfaces.

Now on this chart we're actually showing what the Sole Clean utilizing the Sanifect D2 sanitizer really did. Now keep in mind on these, both the Wetted Boot Dip and/or the Sole Clean enhancement. These are really for the 2000S and 4000S systems. So keep that in mind when looking at this again, this is about contact time. So when you look at these, we've got both really, really good results. We got 99.9, 9% on both of these pathogens. Again, this is using that alcohol blend solution that is just dampening on the footwear and then quickly evaporates in 20 to 30 seconds after application. Again, what we're talking about here is really about how the chemistry does killing on a hard surface and really about that contact time when utilizing the system, we're currently writing a study protocol for boot scrubbers, where we can apply a pathogen to a known soil or protein, and then remove the soil protein and collect the data. So stay tuned. That information will be coming soon. Once we were able to, to create that protocol and do that study.

We're going to have another webinar coming soon, specifically on footwear, the challenge in the hygiene best practice of keeping in mind, come back to the Meritech website come back to our, our Meritech social medias, where you'll see different publications that we'll do either in both a podcast and or a webinar coming up in the near future.

Markets that are best for CleanTech® Automated Handwashing Stations

So what are the applications or markets? The CleanTech® stations are in many markets. As you can see in these photos, we have industrial/manufacturing, commercial, consumer facing and public use. So we have another poll question, Abigail, take it away.

Abigail: All right, everyone, another poll should've just popped up on your screen. Please let us know what industry you're in today.

Paul: All right. Well, you guys, your answer, the poll question, I'm going to break down the various markets and categories.

CleanTech® Stations for Industrial Manufacturing Hygiene

So one of the things I talked about earlier was the industrial manufacturing. Really what we see in that is really you have your food processing, okay? You'll have your cannabis and your cannabis can be either in the grow and or the harvest. You have medical device manufacturing, you have packaging and the clean room and pharma now clean room and pharma can be in a couple of different areas and it kind of breaks down a couple of ways because a clean room could be, you know, both a medical device manufacturing, it could be micro, electronic manufacturing, could also be pharma.

CleanTech® Stations for Commercial Industries

Then within the commercial division, we have healthcare. Okay. Which that healthcare and medical can be anywhere from a hospital, a doctor's office even a dental office, or even maybe a small practice where hygiene is important to do that. You also have government and military, which again, there's a broad spectrum within that category that could be there. And again, back in that you could have different clean room and pharma, because we may be dealing with something as simple as a lab or something like that within those areas.

CleanTech® Stations for Public Use and Customer Facing Industries

Then we have customer facing or public use or what we call away from home hand hygiene. So you really have in that category, what you have is education and daycare that could be universities, it could be cafeterias and those type of environments, then you have travel and leisure. So travel and leisure could be like a cruise ship or a theme park or even a petting zoo. So one of the reasons why that's important is you think about that. So when you're dealing with an allergen, and you can't kill it. And the instant sanitizer will have no effect. You have to wash your hands. So that's really important when you're dealing with those things. The last thing kind of within that customer facing and public use is you have food service, retail, restaurants, and grocery stores. So if, if you look at at food service, traditionally, we've been as a company in back of house, we're seeing more and more in front of house. So people are allowed to actually wash their hands prior to eating, and that's really important. in those type of restaurants or facilities that actually where you're encouraged to eat with your hands. Okay. So we're seeing that resurgence a lot within restaurants. And you think about a grocery store, you know why that would be important, both again, front of house, back of house. If you imagine everybody washing their hands before they come into the produce area and making sure they wash their hands prior to touching all the fruits and vegetables, because there's no one out there, that's actually not touching the avocados.

Abigail: All right. Thank you, Paul. All right. It looks like most of you are in the food and beverage manufacturing, packaging, and cannabis industries. They you so much for participating in the poll. Paul, back to you.

Paul: Thank you again, Abigail. So thank you for sharing that result and thanks for participating in the poll.

Which CleanTech® automatic hand washers are best for each industry for hand hygiene?

So let's kind of move on. Let's go ahead and break down the different systems. So in front of you are really the commercial and public use systems.

CleanTech® automatic hand washing Stations for Public Use and Commercial Businesses

So we have four different models that really fit into that category. Each of these models kind of do the same thing. You know, each of the systems will handle about five people per minute. They're really non-industrial. So they're not really designed for the heavy duty cleaning wash down environment that you find in more of our industrial applications. The system still washes from fingertip to.wrist. The utility requirements for all the CleanTech® models are identical. So you really do. You need that hot and cold water. You need that one and a half inch drain and you need the one 10 volt electrical outlet. From there it takes it over.

Now all of these systems also meet the FDA food code requirements and built within that food code requirements, is not only the standard recommended CDC guidelines of minimum of 20 seconds of manual scrubbing on the hands, but it also states in there that a manual or automated hand washing is allowed to be used in those environments as well. And so that is, is built into that food code..

So now, if we kind of look at these systems kind of going left to right, you look at the CleanTech® ELF it really is capable of mounting into a wall, into a countertop of any material and or in a table Mount, as you see here. Very commonly used within the healthcare and/or those medical spaces. Then you have the CleanTech® ELF-C. Now the CleanTech® ELF-C is a counter mount only system. It is very low profile. It can go into the stainless steel cabinet that you see pictured here as well as then any countertop type of material that you would like to mount that system into. Then we have the CleanTech® 400 system. Again, capable of mounting and it has a few different configurations-it could be a wall-mount, could be an in-counter, can be in this table mount depending on what you need. One of the things that's unique about the system is we have what is called an optional faucet on top. That is there, should you need to be able to do some type of manual scrubbing, should you have heavy soils and debris and keep in mind if you're having different heavy soils and debris please you know, go to one of our podcasts and so forth where we talk about best practices for heavy soils.

And then finally we have the CleanTech® 500-C and what this system was really developed for that nutraceutical /pharmaceutical environments, those areas where you need a compact system that fits really well within a lab or space like that. Maybe an anti room within the hospital where you're mixing drugs and so forth. Again, another versatile hand washing machine that is capable of being wall-mount or in-counter mount, depending on what, and very, very again, low profile and the entry of it's a little bit more sink-like.

CleanTech® Stations that meet Industrial Hand Hygiene Requirements

So now we're going to kind of get into our industrial line. Now really, there's three systems within this industrial line. There's CleanTech® 500EZ, the CleanTech® 2000S and the CleanTech® 4000S. Now what's different about these is they're actually 20 different enhancements and or combinations that you can have there for these systems.

So let's kind of go again, left to right. Talk about some of the basic things. They're up to five users per unit in the 500EZ and 2000S. The CleanTech® 4000S can handle up to 15 people per minute. They're all very industrial systems they're made out of durable three or four stainless steel. They are CIP friendly, so they go into a lot of those environments that you can wash down/hose down. They do have a deeper cylinder, so you're going a little bit beyond the fingertip to the wrist - you're actually going fingertip to almost mid-arm, so you're getting a little bit deeper clean. Again, the same utility requirements as I've mentioned before: hot and cold water, drain, 110 volt outlet and so forth.

Now, something else that's very unique about the industrial line of equipment is really that we have a two and a half gallon solutions container inside each bay of these systems. That you know, will help out and plants so they don't have to change solution very much. So if you look into traditional soap dispenser on a wall that really holds maybe 150, maybe 200 max number of handwashes depending on how, how many times a person pumps and the average time somebody pumps is really three. So there is a lot about wasted product there. When you're looking at the two and a half gallon container, you're getting approximately 1800 handwashes of solution in every single container.

Lean more about why UltraPure is a better alternative to industrial hand soap

A couple of other features I want to go over: one is, is the self-cleaning cycle that's available in the CleanTech® 2000S and CleanTech® 4000S lines. That is that automatic, once a day, system cleaning. It will automatically turn, on cleans itself with a hard surface cleaner that's at a higher concentration, and again, only takes about 20 seconds. Another thing that's really important to note about the CleanTech® 4000S is something that the engineering department is working on right now. And a lot of concern has been brought up recently within the last 60 days of how do we continue to use this system and still maintain social distancing. Please, hang on tight, give us another, you know, few weeks we will actually be releasing information about an additional enhancement you can have for that CleanTech® model that will allow you to still use every bay of that system and still practice social distancing as we're creating a social distancing shield that can go between bays one and two, and between two and three.

Why Choose CleanTech® automatic hand washing stations over an Industrial Sink?

So let's kind of go through the values of the CleanTech® systems. You know, you have increased compliance. We've talked about that. We have the clinically backed data it's consistently effective again, that's where automation kicks in and does the deal. Sustainable and eco-friendly, that's important because we're wasting no water during the hand wash. We demonstrate our commitment to quality. You know, we exceed the SQF, BRC, USDA, you know, even the FSMA guidelines you have for hygiene, but there's something a little bit more than that when it comes to the demonstration and commitment to quality.

If you're a co-packer or your selling your products to your customer. One of the things that the CleanTech® Systems do demonstrate is your commitment to making sure that you have a quality environment. You're showing them your commitment to making sure that you're improving on your hygiene standards. And lastly, I want to talk about, you know, promotes healthy skin. One of the things in the way we wash is, is really using these again, these 40 nozzles to wash and clean the hands effectively every single time with the right blend and chemistry of the solutions is balanced so that you can make sure that it's not detrimental to the overall skin effects in time.

One of the things that we want to do is make sure that when people are washing frequently, which you have to do. I mean, the minimum number of hygiene events in a food environment is five. The number of events in food service, maybe much greater than that, or even in a medical setting. So you want to be able to make sure that people can really wash their hands frequently without the detrimental effects of damaging their skin, which does not promote healthy skin.

So the systems are designed to accommodate any hygiene zone and we'll be releasing a new webinar about hygiene zoning specifically soon around hand hygiene, PPE, footwear hygiene, and so forth as people come into the area. And I think there's also a, this is actually a video within the deliverables. We're going to actually send you a YouTube link that you can actually watch this video and so forth.

One of the other things to really talk about with hygiene zoning is really something that we're working on. Meritech in conjunction with food safety magazine is actually working out what it's called the hygiene toolbox. It's a six module release that's being released every six to seven weeks throughout 2020 talking about really the six important modules focused around employee hygiene. Module one has already been released and it really module one really talks about creating the culture of hygiene and what that means for an organization. And within this module really have four segments designated out that are really important in good information and good assets to deliver. Not only for, you know, your C class and your executive management, then you have information and deliverables for your middle management, then you have information for your team member leaders as well as then your team members. Remember. Within that hygiene toolbox again, the first one was about the culture. The second one is about best practices in hand hygiene. The third one is about footwear hygiene. The fourth one is really now getting into the flow and the design of hygienic zoning, and that's becoming more and more popular as plants grow and how these plants and facilities get designed.

Sostay tuned for that. Definitely go to the food safety magazine, sign up it's for free and you can get the different leases in the assets from that hygiene toolbox.

The toolbox is now on Meritech's website, you can access it here.

Okay. Everyone it's time for another poll question, Abigail.

Abigail: All right. Thank you, Paul. As you're answering this final poll, I just want to remind everyone that we'll be sending the follow-up email with all the links to the resources mentioned throughout this presentation, including that Employee Hygiene Toolbox that Paul just mentioned. Paul, while everyone is answering the poll. We had a question come in: how does CleanTech® replace the scrubbing action of a manual handwash?

Paul: Really we're replacing that scrubbing action or that, that friction of the two hands together with those 40 jet nozzles, those 20 per hand, again, that are designed in an optimal pattern to be able to spray into the hand as well as then, when the cylinder rotates around the hand, to be able to remove those pathogens to remove those skin cells and so forth that that need to slough off where the pathogens actually lie.

And that replaces that friction. So you think about that when you rub your hands together. Okay. Yes. You're, you're helping to remove that same dead skin, so forth, but we're doing that a different way. The water that we use in the high pressure nozzles, the low flow are able to get into the cracks and crevices of the skin.

So when you zoom in close on the skin, you can see it's full of these cracks and crevices. You know, we all have different lines and so forth in our hands and we're able to get into those a little better.. When you rub your hands together, you're actually may be actually forcing some of these pathogens directly further into those cracks and crevices and where you have a little bit of maybe microbial load buildup.

And so we replaced that action and behavior. Also, one of the things with the 40 nozzles does it really stimulates the skin. It really gives you almost this euphoric feeling when you're washing your hands the correct way.

Abigail: All right. Thank you, Paul. All right, let me close the poll here and share the results. It looks like for most of you, the thing that challenges you most in your hygiene zone is compliance monitoring. All right. Thank you for participating in that final poll, Paul, back to you.

Paul: Well, compliance monitoring is really, really important and it's really difficult when you're referring to manual handwashing. There's really only one way to address that, and that's really policing the behavior unless you'd look differently. There's different ways to look at that. And one of those is obviously with every CleanTech® system, we're automatically giving you that compliance, monitoring and so forth.

You know, one of the things I've noticed over the last 28 years that I've been in this industry is the way the plants are built and designed. You know, I call that the "build a box" story. And every time you see a food plant, They build a box and hygienic zone is in a certain area, or it may be in multiple areas coming in the plant. As that business grows, and as that business changes they build another box onto that building. What happens in that build is you actually lose a little bit of that operational flow and that throughput. You know, you have to think about where are the people traveling from A to B, you know, are they maybe kind of moving from a raw to an RTE area or are they dealing with an allergen within that area of that plant?

And so that's really where, when you're talking about hygienic zoning, where you're talking about operational flow and throughput, you really have to look at all these aspects from that. And so that's what, one of the things and the benefits of Meritech. So as well as then within those hygiene zones and something new, again, that we're being asked more of is, you know, how do you, then again, you need to perform a quality hygiene event, but then how do you also practice social distancing to those those areas? And what do you do to make sure that you optimize that flow as well as not compromise a hygiene event? And that's really important, is making sure that you never compromise quality for anything. So that's really important. Again, that's when Meritech looks at it and how you move people through quickly CleanTech® systems do that as well as provide that social distancing.

And when you're looking at your hygiene zones, and when you're looking at your facilities, again, you have to focus on your people, your place, and your products. You need to understand these things, to understand the challenges you face when it comes to hygiene.

So Meritech, doesn't consider ourselves a simple manufacturer or a simple provider of equipment. It's a much, much larger than that. We're very educational and consulting. What we do is work in partnership with our customers, develop a hygiene zone. We've not looking at just one piece of equipment, but also where it should be placed in the flow of employees coming in and out of that facility. It's about eliminating the human behavior variable and the handwash as well as from the group of employees entering and touching different aspects of the facility. We're looking at where are the doorknobs? Where's the time clock? Where are the gowns? What are the things that have to touch? That's where Meritech adds value, not just providing the technology and equipment, which is very unique, we are consulting with our customers, with the goal to become an extension of their organization.

At this point in the webinar we start the open Q&A. You can find the questions and answers discussed during the webinar here, as well as additional questions we were unable to get to in the time alloted.

The Speaker:

Paul Barnhill is Chief Technology Officer and head Engineer at Meritech, the leader in automated employee hygiene. He has over 28 years of experience working with professionals in food manufacturing, healthcare, and foodservice to understand the challenges they face when creating hygiene programs and how to overcome these obstacles through education and automated technologies. Helping food processing and packaging facilities produce safe and healthy products through hygiene excellence is a passion for him and he often speaks on best practices in hand hygiene, footwear sanitation, and the science behind pathogen removal.

Paul Barnhill is Chief Technology Officer and head Engineer at Meritech, the leader in automated employee hygiene. He has over 28 years of experience working with professionals in food manufacturing, healthcare, and foodservice to understand the challenges they face when creating hygiene programs and how to overcome these obstacles through education and automated technologies. Helping food processing and packaging facilities produce safe and healthy products through hygiene excellence is a passion for him and he often speaks on best practices in hand hygiene, footwear sanitation, and the science behind pathogen removal.