Navigating Food Safety Inspections

Ensuring food safety is paramount for any food processing facility, as it protects consumers from potential health hazards that may arise from contaminated or improperly handled food products. The role of food safety inspections in maintaining the quality and integrity of food processing operations cannot be overstated. While navigating these inspections can present some complexities, proper preparation and adherence to regulations can help food processing facilities meet or even exceed the required standards. This blog post delves into essential tips for successfully navigating food safety inspections in food processing facilities.

Understanding the Applicable Regulations for Food Safety Inspections

It is essential to keep in mind that regulations governing food processing may vary depending on your location. Therefore, it is vital to conduct thorough research and familiarize yourself with the relevant regulations that apply to your facility. For instance, you may need to comply with different local, state, and federal guidelines, depending on your location. Additionally, you should understand the specific requirements for your facility type, such as Good Manufacturing Practices (GMPs), Hazard Analysis and Critical Control Points (HACCP), and the Food Safety Modernization Act (FSMA). By understanding these regulations, you can ensure that your facility is compliant and well-prepared for inspection. Furthermore, staying up-to-date with the latest trends and changes in regulations can help you continuously improve your facility's food safety practices.

It is essential to keep in mind that regulations governing food processing may vary depending on your location. Therefore, it is vital to conduct thorough research and familiarize yourself with the relevant regulations that apply to your facility. For instance, you may need to comply with different local, state, and federal guidelines, depending on your location. Additionally, you should understand the specific requirements for your facility type, such as Good Manufacturing Practices (GMPs), Hazard Analysis and Critical Control Points (HACCP), and the Food Safety Modernization Act (FSMA). By understanding these regulations, you can ensure that your facility is compliant and well-prepared for inspection. Furthermore, staying up-to-date with the latest trends and changes in regulations can help you continuously improve your facility's food safety practices.

Learn more about FSMA compliance requirements

Establishing Robust Standard Operating Procedures (SOPs) for Food Safety Inspections

Standard Operating Procedures (SOPs) are an integral part of maintaining food safety standards. They serve as a roadmap for all critical processes, ensuring that every step is executed correctly and consistently. It is essential to develop and implement comprehensive SOPs tailored to your facility's specific needs and processes. These SOPs should cover all aspects of handling, storage, processing, sanitation, and employee training.

Regular review and update of your SOPs are crucial to ensure that they remain accurate and up-to-date. This process involves identifying any gaps or deficiencies in the existing procedures and making necessary adjustments. Following the SOPs consistently is equally essential, and staff members should be trained on their content and importance.

Well-documented and implemented SOPs demonstrate your facility's commitment to food safety and can help streamline the inspection process. Inspectors will look for evidence of SOPs, how they are followed, and their effectiveness in ensuring food safety. Having SOPs in place can also help identify areas for improvement and provide a basis for ongoing employee training.

Watch our webinar on establishing proper SOPs

Implement Good Manufacturing Practices (GMPs) for Food Safety Inspections

Good Manufacturing Practices (GMPs) are a fundamental aspect of maintaining a high level of food safety in any food processing facility. They provide a systematic approach to ensuring that all aspects of the facility, from equipment maintenance to employee hygiene, are designed to minimize the risk of food contamination. Adhering to GMPs can not only help ensure food safety but also enhance the overall efficiency and quality of your operations.

Good Manufacturing Practices (GMPs) are a fundamental aspect of maintaining a high level of food safety in any food processing facility. They provide a systematic approach to ensuring that all aspects of the facility, from equipment maintenance to employee hygiene, are designed to minimize the risk of food contamination. Adhering to GMPs can not only help ensure food safety but also enhance the overall efficiency and quality of your operations.

To implement GMPs, it is essential to train your staff on the guidelines and their importance. Conduct regular inspections of your facility to identify any deficiencies or areas for improvement, and address them promptly. This could involve adjusting your sanitation procedures, improving employee training, or upgrading your equipment.

GMPs require a facility layout that reduces cross-contamination, with proper ventilation and space. Regular maintenance, hygiene, and pest control also play a critical role in maintaining a compliant and efficient facility. Regular training, inspections, and issue resolution are essential.

Learn about the core hygienic zoning steps for manufacturing

Develop and Maintain a HACCP Plan for Food Safety Inspections

Developing and maintaining a Hazard Analysis and Critical Control Points (HACCP) plan is a critical aspect of ensuring food safety in any food processing facility. HACCP is a systematic approach that involves identifying and analyzing potential hazards in food production and implementing controls to minimize or eliminate them.

To develop an effective HACCP plan, it is essential to understand the specific hazards associated with your facility, products, and processes. This involves conducting a thorough hazard analysis, which identifies potential hazards, their likelihood of occurrence, and the severity of their impact on consumers. Based on this analysis, critical control points (CCPs) are established, which are specific points in the process where controls can be implemented to prevent or eliminate the hazards. I have

Establish monitoring procedures to ensure CCPs are controlled by measuring and recording critical limits like temperature, pH, or water activity. Regularly review and update HACCP plan to identify any necessary adjustments and train staff on updated procedures. An effective HACCP plan can prevent foodborne illness, protect customers, and maintain facility reputation.

Download our Food Safety Hand Washing Posters

Prioritize Employee Training and Awareness for Food Safety Inspections

It's crucial to prioritize employee training and awareness in any food processing facility. Employees play a critical role in ensuring food safety, and it's essential to ensure that they receive comprehensive training on all aspects of food handling, from personal hygiene to proper equipment and chemical handling. Encourage a culture of accountability and empower employees to report any food safety concerns promptly. Regularly reinforce these practices through ongoing communication, signage, and training sessions.

One effective way to promote employee engagement and awareness is to involve them in the development and implementation of food safety protocols. By involving employees in this process, you can help them understand the importance of following food safety guidelines and empower them to take ownership of their role in ensuring food safety. It's also essential to provide ongoing training and education to ensure that employees remain up-to-date on the latest food safety practices and regulations. This includes regular refresher courses and training sessions, as well as updates on any changes to protocols or regulations.

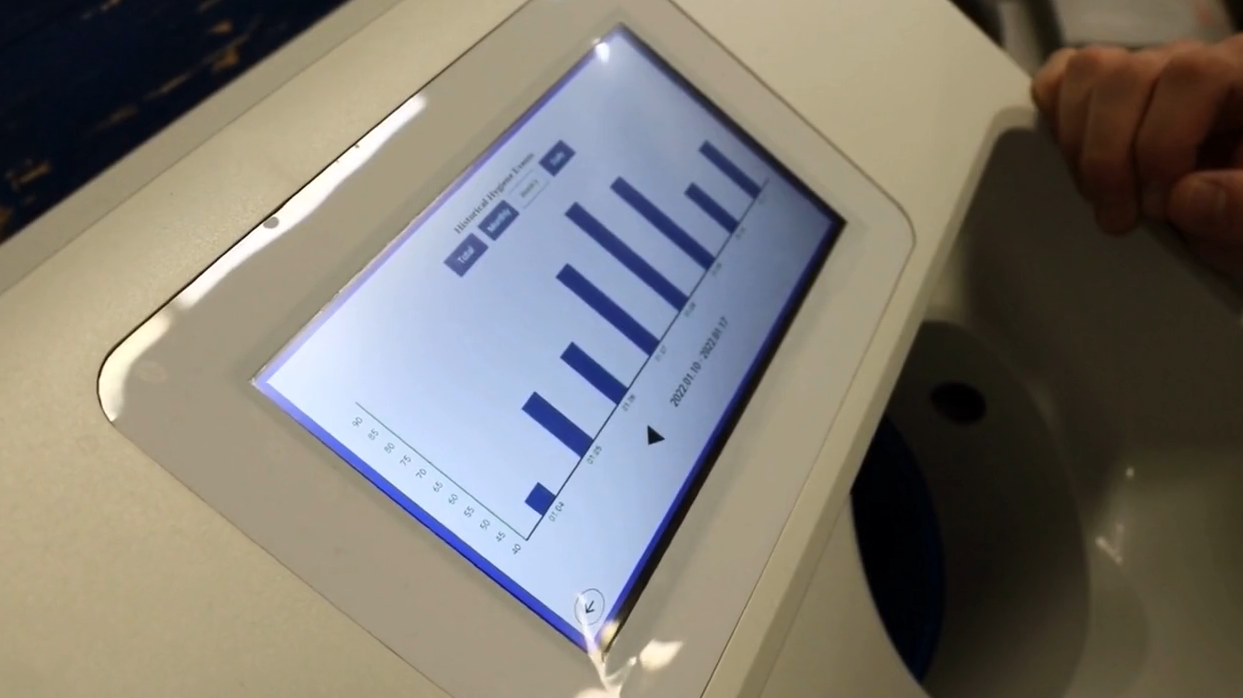

CleanTech® Automated Handwashing Stations play a crucial role in employee food safety training in food processing facilities. These innovative stations are designed to ensure proper hand hygiene consistently from employee to employee. By incorporating CleanTech® Automated Handwashing Stations into hygiene zones, facilities can instill a culture of hygiene and reinforce the importance of handwashing in maintaining food safety standards. Additionally, these stations can track and record handwashing compliance data, allowing facilities to monitor and evaluate employee compliance with hand hygiene protocols. Incorporating CleanTech® Automated Handwashing Stations into hygiene zones not only helps prevent cross-contamination and the spread of foodborne pathogens but also demonstrates a commitment to maintaining a safe and sanitary work environment.

Learn more about how CleanTech® EVO Works

Maintain Comprehensive Documentation for Food Safety Inspections

When it comes to maintaining comprehensive documentation, digital systems can be a game-changer for food processing facilities. These systems allow you to store and access critical information easily, such as employee training records, cleaning and sanitation schedules, and equipment maintenance logs. By using digital systems, you can streamline your documentation processes, minimize errors, and ensure that records are up-to-date.One significant advantage of digital systems is that they can provide real-time data and analytics, allowing you to identify trends and potential issues quickly. For example, if you notice a recurring problem in a particular area of your facility, you can use data from your digital systems to investigate the root cause and take corrective action.

CleanTech® plays a significant role in helping food processing facilities maintain comprehensive documentation for food safety inspections. By using digital systems, such as CleanTech®'s touchscreen display, facilities can streamline their documentation processes and ensure that compliance records are accurate and up-to-date. The real-time compliance data provided by these systems enable facilities to identify trends and potential issues quickly, allowing for prompt corrective action. Incorporating CleanTech® into hygiene zones not only promotes proper hand hygiene but also demonstrates a commitment to maintaining a safe and sanitary work environment. By prioritizing comprehensive documentation, facilities can enhance their food safety practices and successfully navigate food safety inspections.