How to Measure Hand Hygiene Compliance for Food Safety

Proper hand hygiene is a crucial element in the prevention of foodborne illnesses, making it essential for food establishments to have effective measures in place to monitor and maintain good hand hygiene practices. A system for measuring hand hygiene compliance is a valuable tool for achieving this. In this blog post, we will delve into various methods and tools that can be utilized in food establishments to measure hand hygiene compliance.

Why Measure Hand Hygiene Compliance?

It's no secret that effective hand hygiene practices can prevent the spread of harmful pathogens that can cause foodborne illnesses. Hand hygiene audits and Good Manufacturing Practices (GMPS) are essential tools that can help identify gaps in food safety training. Audits can provide insights into the overall compliance levels of an establishment, and GMPS can help establish a framework for effective hygiene practices.

It's no secret that effective hand hygiene practices can prevent the spread of harmful pathogens that can cause foodborne illnesses. Hand hygiene audits and Good Manufacturing Practices (GMPS) are essential tools that can help identify gaps in food safety training. Audits can provide insights into the overall compliance levels of an establishment, and GMPS can help establish a framework for effective hygiene practices.

By identifying gaps in training, establishments can develop targeted interventions to address the areas where compliance is lacking and ensure that employees are properly trained in effective hand hygiene practices. Overall, the relationship between hand hygiene, pathogen spread, audits, and GMPS underscores the importance of proper training and continuous monitoring to ensure that food safety standards are met and customers are protected from foodborne illnesses.

Learn about sustainable solutions for good hygiene practices in the food industry

Direct Observation Methods to Measure Hand Hygiene Compliance

While direct observation can be an effective method for measuring hand hygiene compliance, there are some limitations to consider. For example, individuals may change their behavior when they know they are being observed, leading to inaccurate data. To mitigate this issue, observers should be discreet and blend in with the environment as much as possible. Additionally, direct observation can be a costly and time-consuming method, as it requires trained observers to monitor employees consistently.

While direct observation can be an effective method for measuring hand hygiene compliance, there are some limitations to consider. For example, individuals may change their behavior when they know they are being observed, leading to inaccurate data. To mitigate this issue, observers should be discreet and blend in with the environment as much as possible. Additionally, direct observation can be a costly and time-consuming method, as it requires trained observers to monitor employees consistently.

Despite these limitations, direct observation can be a useful tool for establishing a culture of accountability for hand hygiene practices among employees. By providing immediate feedback and identifying areas where improvement is needed, food establishments can address compliance gaps promptly and ensure that their employees are following established hygiene protocols. Observers can also use direct observation to identify areas where additional training or resources may be needed to support optimal hand hygiene practices. Overall, while direct observation may not be the most efficient method for measuring hand hygiene compliance, it can be a valuable tool for promoting a culture of food safety and accountability in food establishments.

Visit our Food Safety Toolbox for food safety culture resources

Hand Hygiene Audits to Measure Hand Hygiene Compliance

Hand hygiene audits are an essential part of any food establishment's hygiene program. These audits involve a thorough and comprehensive review of the establishment's hand hygiene practices. The process typically involves reviewing records and logs, interviewing employees, conducting direct observations, and reviewing the establishment's hand hygiene policies and procedures. The goal of hand hygiene audits is to identify areas where compliance is lacking and to develop a plan to address these areas. The results of these audits can be used to develop targeted training programs, identify areas where additional resources are needed, and monitor ongoing compliance levels.

One benefit of hand hygiene audits is that they provide valuable insights into overall compliance levels over time. Audits can be conducted on a periodic basis, such as monthly or quarterly, to monitor progress and identify trends. This information can then be used to make adjustments to the establishment's hygiene program to ensure ongoing compliance. Another benefit of hand hygiene audits is that they can be conducted by either internal staff or external auditors. Internal staff may already be familiar with the establishment's policies and procedures, making it easier to identify areas where compliance is lacking. External auditors, on the other hand, may provide a fresh perspective and identify areas that internal staff may overlook.

Download our Hand Hygiene Audit Tool

Automated Hygiene to Measure Hand Hygiene Compliance

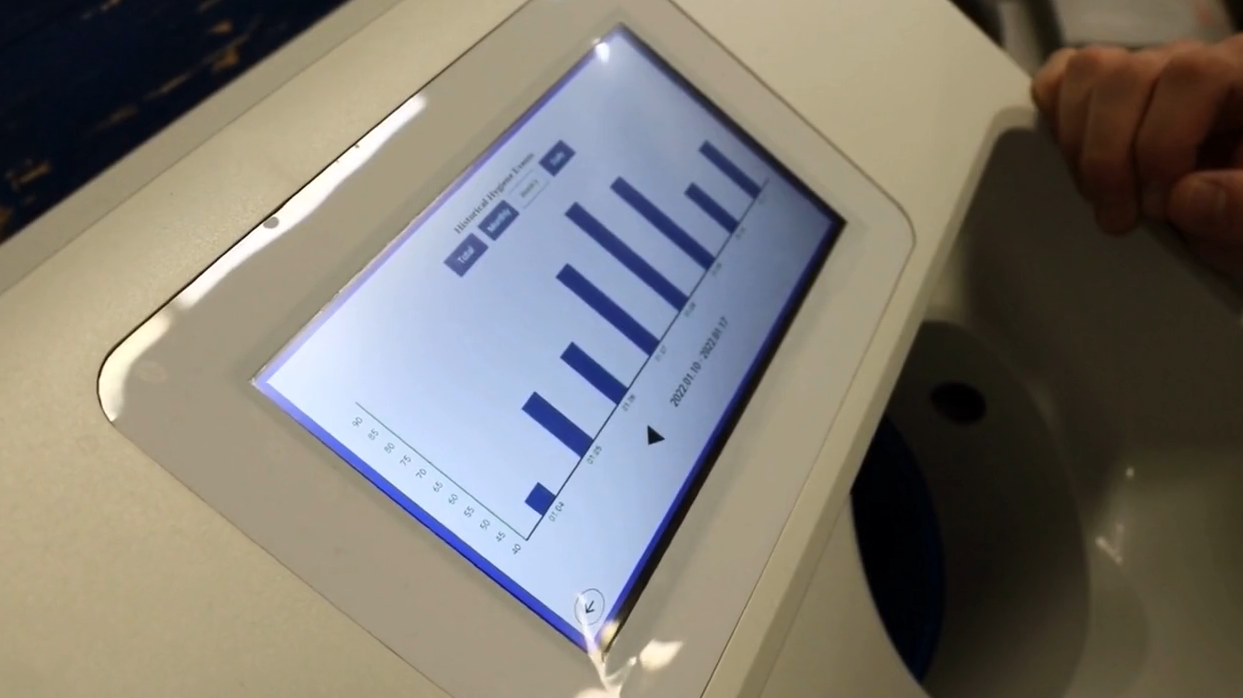

CleanTech® Automated Handwashing Stations are revolutionizing the food safety industry by providing an accurate and unbiased method of measuring hand hygiene compliance. CleanTech® offers a user-friendly touchscreen display that provides valuable compliance tracking data for food safety managers. This data can be used to identify trends and patterns in hand hygiene practices across different shifts and departments. This technology is especially useful in larger establishments where direct observation may not be feasible or practical.

Incorporating automated hand hygiene systems in food processing facilities can revolutionize hygiene monitoring by offering an unbiased and efficient approach to tracking compliance rates. These systems can identify areas of non-compliance and help develop targeted interventions, thus ensuring that hand hygiene compliance remains a top priority. Additionally, automated systems eliminate observer bias, providing an accurate reflection of hand hygiene practices and effectively minimizing the risk of foodborne illnesses.

Proper hand hygiene practices are crucial for food safety. A robust system to measure hand hygiene compliance, including direct observation, hand hygiene audits, and automated hand hygiene can identify areas for improvement and ensure adherence to hygiene protocols. Consistent monitoring and addressing of hand hygiene compliance can minimize the risk of foodborne illnesses and provide safer experiences for consumers.

Proper hand hygiene practices are crucial for food safety. A robust system to measure hand hygiene compliance, including direct observation, hand hygiene audits, and automated hand hygiene can identify areas for improvement and ensure adherence to hygiene protocols. Consistent monitoring and addressing of hand hygiene compliance can minimize the risk of foodborne illnesses and provide safer experiences for consumers.