How to Measure Food Safety Culture at Your Facility

Say you’ve fully implemented a food safety culture program at your facility. What next? You might find yourself asking how to measure food safety culture. It’s not exactly the most tangible thing in food safety. Luckily there Is a way that you can notice how much an improved food safety culture has impacted your facility.

How to Measure Food Safety Culture with Data

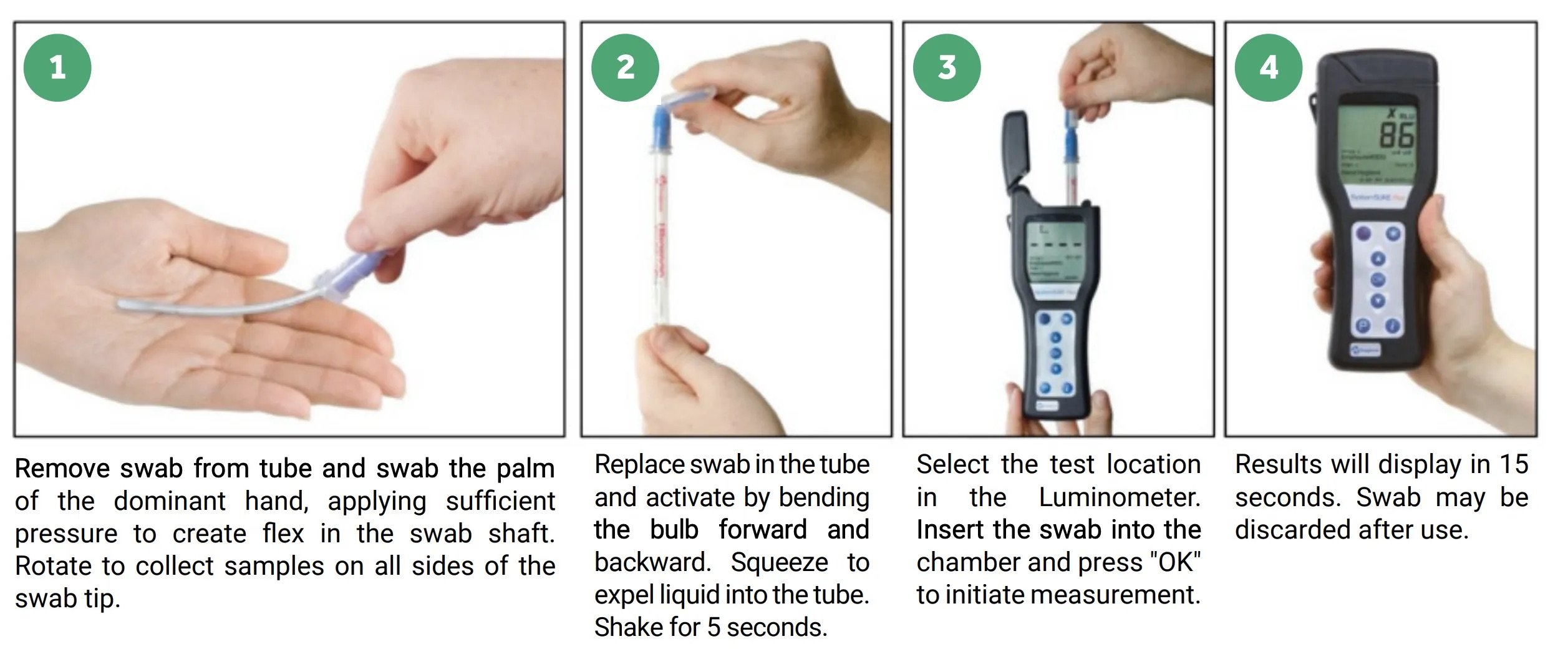

The most effective way to measure if your food safety culture has improved is by validating your hygiene SOPs. The easiest way to do this is with ATP Testing which can show hand hygiene compliance with a simple hand swab. You can swab your employees’ hands before you start a food safety culture training and see just how many of them are washing effectively. After the training is completed and a few days have passed you can then perform another round ATP Tests and compare the results.

There are several things to consider when using an ATP Test for hand washing procedure validation such as understanding and determining if a percentage reduction or pass/fail limit method will be used, knowing the challenges of each, and setting your targets. We go over all of this in our in-depth ATP testing guide which you can download here.

Companies that have implemented automated hygiene are able to easily train employees on the importance of a strong food safety culture. By making the hand washing and boot sanitizing process easier for their employees they can focus on why food safety is important rather than retraining employees on how to properly wash their hands and footwear. Plus, CleanTech® Automated Hand Washing Stations have been clinically proven to remove 99.9% of pathogens so food safety leaders can rest assured that all their employees are receiving the perfect hand wash.

Learn more about the benefits of creating a food safety culture!

How Pecan Deluxe Candy Company Used Automation and ATP Testing for Data-Driven Behavior Change

Pecan Deluxe Candy Company is a Texas-based manufacturer of baked goods, praline nuts, sauces, and cookie dough for a variety of ice cream brands around the world. Over the past few years, they have made investments in automated hygiene technology to ensure food safety and demonstrate their commitment to food safety to their customers. Their investment in automated hygiene technology has been recognized in the industry resulting in them being recently awarded the 2021 Food Quality and Safety Award by Food Quality and Safety Magazine.

They proved that their hygiene processes improved by using ATP Testing. ATP Testing has been used by many of our partners to validate their hygiene SOPs and has shown food safety leaders across the industry how automation can eliminate hygiene concerns that arise from using manual hygiene protocols.

“[Pecan Deluxe’s] automated hand- and boot-washing system, along with more training focused on personal sanitation, led to a significant improvement in employees using the system. The current level of compliance based on hand swabs is 98.3%, compared with less than 95% before the new system was installed.”

-Food Quality and Safety Magazine

Learn more about why automation is best for food safety in our eBook!