Industrial Sinks vs. CleanTech® EVO Industrial Automated Handwashing Stations

Industrial sinks are a common option for high throughput areas for industrial companies like:

- Food processing and packaging

- Pet food manufacturing

- Medical device manufacturing

- Pharmaceuticals and cleanrooms

- & more industries!

However, there are some major pitfalls of industrial sinks to be aware of when implementing a hand hygiene program at your facility. To avoid these contamination risks, a good alternative for these environments are industrial automated handwashing stations.

So what is the difference between using industrial sinks that rely on manual handwashing vs automatic handwashing stations? Let’s take a look:

Reliability and Consistency of Handwashing

The first key difference between industrial sinks and CleanTech® industrial handwashing stations is the reliability and consistency of the hand wash performed by your team. Effective manual handwashing requires many steps including rubbing lather on the back of the hand, between the fingers and under the nails, and more before rinsing and drying completely. To ensure all hand hygiene steps are followed, a company must train and re-train staff on the correct handwashing procedures to ensure product quality and consumer safety. Even with this training, companies are dependent on employees to be diligent in performing each hand hygiene steps correctly and for the proper amount of time to ensure pathogen removal.

The first key difference between industrial sinks and CleanTech® industrial handwashing stations is the reliability and consistency of the hand wash performed by your team. Effective manual handwashing requires many steps including rubbing lather on the back of the hand, between the fingers and under the nails, and more before rinsing and drying completely. To ensure all hand hygiene steps are followed, a company must train and re-train staff on the correct handwashing procedures to ensure product quality and consumer safety. Even with this training, companies are dependent on employees to be diligent in performing each hand hygiene steps correctly and for the proper amount of time to ensure pathogen removal.

Which hand hygiene method is best for your facility? Find out here!

Instead, with CleanTech® industrial handwashing stations, employees simply insert their hands into the station, and the photo-eye sensor begins the handwashing event. Water and solution move in a cylindrical pattern long enough to ensure that all parts of the hand, including the backs, palms and fingertips, are evenly cleansed. The result is 99.9% of pathogens removed and effective hand hygiene achieved.

Compliance Tracking for QA/QC

Product quality and consumer safety can be directly impacted by the hand hygiene process of your team. Manual hand washing methods like using an industrial sink requires a manual quality assurance method like policing behavior or the secret shopper method.

Download our secret shopping guide here!

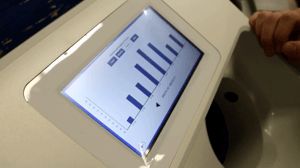

Every CleanTech® automated industrial handwashing station exceeds the most stringent CDC, FSMA, BRC, SQF and NSF requirements while providing QA/QC teams with handwash tracking for SOP validation. On each station there is a touchscreen display where managers can access detailed compliance tracking data to ensure that their teams and shifts are utilizing proper time for hand hygiene before they enter production zones.

Every CleanTech® automated industrial handwashing station exceeds the most stringent CDC, FSMA, BRC, SQF and NSF requirements while providing QA/QC teams with handwash tracking for SOP validation. On each station there is a touchscreen display where managers can access detailed compliance tracking data to ensure that their teams and shifts are utilizing proper time for hand hygiene before they enter production zones.

Reduced Hand Wash Time

In an industrial environment with lots of employees, getting large shifts through hygiene zones quickly is key. With an industrial sink the proper time for a hand wash is at least 20 seconds.

Using an industrial handwash station is much faster -- only 12 seconds! With multi-bay systems like the CleanTech® EVO Three, 15-20 employees can wash their hands every minute.

Cross-Contamination Touch Points

Industrial companies need all employees to follow proper hygiene protocols to ensure product quality and consumer health. However, while many team members may complete all the proper steps, they may not be aware of all the cross-contamination points that exist on industrial sinks that can contaminate clean hands. Manual faucets and manual soap dispensers, common on industrial sinks, are two key cross-contamination points.

Learn how CleanTech® works in this webinar hosted by our CTO Paul Barnhill

.png?width=300&height=400&name=MicrosoftTeams-image%20(13).png) With industrial CleanTech® automated handwashing stations, those cross-contamination touch points are eliminated. With these no-touch systems, photo-eye sensors automatically start the system to complete the handwash. After the cycle is done, employees don’t need to worry about turning off faucets, the system stops automatically so all they need to do is dry their hands.

With industrial CleanTech® automated handwashing stations, those cross-contamination touch points are eliminated. With these no-touch systems, photo-eye sensors automatically start the system to complete the handwash. After the cycle is done, employees don’t need to worry about turning off faucets, the system stops automatically so all they need to do is dry their hands.

Skin Health

In industrial environments it’s not uncommon for employees to wash their hands multiple times throughout the day -- at the start of shifts, after breaks and when coming back from lunch. When using a manual method like industrial sinks, the soap used could be lacking moisturizers to help promote good skin health.

Skin health is as important to hand hygiene as the handwashing process is. At Meritech all of the hygiene solutions used with our industrial CleanTech® automated handwashing stations have moisturizers to promote healthy skin.

Hygiene Culture Program Support

One of the best parts of CleanTech® automated handwashing stations? The educational resources and ongoing support you’ll receive from our team! When you choose automated handwashing stations for your facility, you join the hygiene revolution with other industrial manufacturing leaders like you who are ensuring employee health, consumer safety and product quality, one automated handwash at a time.

Learn more about the Hygiene Revolution

We hope that this blog was helpful to you as you consider a handwashing method for your industrial facility. If you have any other questions please contact us at 1 800-932-7707