Ensuring Food Safety Compliance at Your Facility

Ensuring food safety and compliance is crucial for protecting consumers, maintaining your business's reputation, and building customer loyalty. By prioritizing food safety and adhering to regulations, you demonstrate your commitment to providing safe, high-quality products. In today's society, where consumers are increasingly conscious about their food choices, companies that prioritize food safety are more likely to be chosen.

Understanding Food Safety Compliance

It is of utmost importance to prioritize the safety of the food produced in your facility, not only for the well-being of consumers but also for the success and reputation of your business. With an increasing emphasis on food safety, it is crucial that each stage of the food production process adheres to regulations and industry standards.

It is of utmost importance to prioritize the safety of the food produced in your facility, not only for the well-being of consumers but also for the success and reputation of your business. With an increasing emphasis on food safety, it is crucial that each stage of the food production process adheres to regulations and industry standards.

By prioritizing food safety compliance, you demonstrate your commitment to providing safe and high-quality products to your customers. This commitment builds trust and confidence in your brand, ultimately leading to customer loyalty and repeat business. Consumers today are more conscious about the food they consume, and they are more likely to choose products from companies that prioritize food safety.

Importance of Food Safety Compliance

Non-compliance with food safety regulations can have serious consequences for both consumers and businesses. The potential risks of non-compliance are numerous and can result in public health emergencies, foodborne illnesses, and even loss of life. When food safety standards are not met, harmful bacteria, pathogens, and contaminants can contaminate the food, leading to outbreaks of illnesses and diseases.

Learn about FSMA Compliance Requirements

In addition to the health risks, there are also legal consequences associated with non-compliance. Regulatory agencies have strict guidelines in place to ensure that food manufacturers and facilities adhere to food safety regulations. Failure to comply with these regulations can result in hefty fines, legal action, and even the closure of the business. Not only do you risk damaging your reputation, but you also risk losing the trust and loyalty of your customers.

Benefits of Food Safety Compliance

Building trust with consumers is essential for the success of any food business. When it comes to food safety compliance, trust is built by consistently delivering safe and high-quality products to your customers. By prioritizing food safety and adhering to regulations and industry standards, you demonstrate your commitment to their well-being.

One way to build trust is by being transparent about your food safety practices. Communicate with your customers about the measures you take to ensure the safety of your products. This can be done through your website, product packaging, or even in-store signage. By providing information about your food safety protocols, you give customers peace of mind and show them that you take their safety seriously.

Implementing Good Manufacturing Practices (GMPs) for Food Safety Compliance

Good manufacturing practices (GMPs) are the foundation of maintaining food safety standards in any food production facility. These practices encompass a set of guidelines and procedures that ensure the safety, quality, and integrity of the food products being manufactured.

Creating a Food Safety Plan

Identifying potential hazards and establishing preventive measures is a crucial aspect of food safety compliance. By thoroughly understanding the potential risks associated with your food production process, you can take proactive steps to mitigate them and ensure the safety of your products.

Identifying potential hazards and establishing preventive measures is a crucial aspect of food safety compliance. By thoroughly understanding the potential risks associated with your food production process, you can take proactive steps to mitigate them and ensure the safety of your products.

Learn how to foster food safety culture ar your facility!

To begin with, it is important to conduct a thorough hazard analysis of your facility. This involves identifying any biological, chemical, or physical hazards that could potentially contaminate your food. Biological hazards can include bacteria, viruses, or parasites, while chemical hazards can involve the presence of toxins or allergens. Physical hazards refer to any foreign objects that may accidentally find their way into the food, such as glass or metal fragments.

Training and Education

Providing regular training sessions for employees and keeping them up to date with industry regulations is essential for maintaining food safety compliance. By investing in employee training, you ensure that your staff is knowledgeable about proper food handling, storage, and preparation techniques. This helps to prevent contamination and minimize the risk of foodborne illnesses.

Download training resources in our Food Safety Toolbox!

Regular training sessions can cover a range of topics, including hygiene practices, cross-contamination prevention, allergen management, and the proper use of personal protective equipment. By keeping employees informed about the latest industry regulations, you enable them to stay compliant with the most up-to-date food safety standards.

Documenting and Analyzing Data

Keeping records of tests and inspections is a crucial aspect of food safety compliance. By documenting all the tests and inspections conducted in your facility, you create a valuable resource that can be used to track and assess the safety of your food products. These records serve as evidence that you are actively monitoring and evaluating the effectiveness of your food safety measures.

When it comes to analyzing data, it is important to go beyond simply recording the results of tests and inspections. By carefully analyzing this data, you can identify trends or areas for improvement in your food production process. For example, if you notice a recurring issue with a particular ingredient or equipment, you can take corrective action to address the problem and prevent it from happening again in the future.

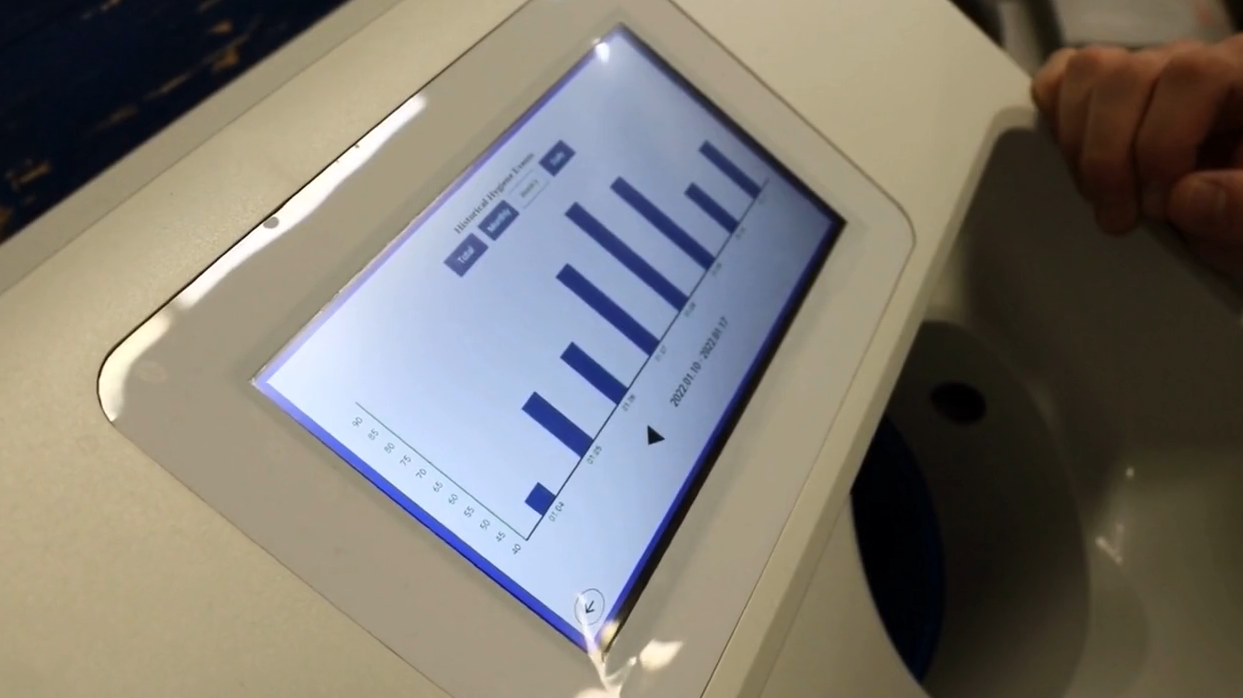

CleanTech® Automated Handwashing Stations offer a solution to ensure compliance with food safety regulations by tracking valuable handwashing data. These innovative stations are equipped with advanced technology that monitors and records every handwashing event, providing real-time data on compliance rates. By tracking handwashing data, food production facilities can identify any non-compliance issues and take corrective action promptly. This not only helps prevent the spread of harmful bacteria and pathogens but also demonstrates a commitment to food safety and customer well-being.

Learn how CleanTech® tracks valuable compliance data!

With CleanTech® Automated Handwashing Stations, businesses can build trust with consumers by transparently showcasing their dedication to maintaining high standards of hygiene and compliance. By implementing these automated handwashing stations, facilities can not only meet regulatory requirements but also enhance their food safety practices and protect their brand reputation.

Conducting Regular Audits and Inspections for Food Safety Compliance

Regular audits and inspections play a crucial role in maintaining food safety compliance and ensuring the highest standards of quality and safety in your facility. These routine assessments help identify any potential gaps or areas for improvement in your food production process, allowing you to take proactive steps to address them.

Internal audits are an essential part of any food safety compliance program. By establishing an internal audit program, you can regularly assess your facility's adherence to food safety regulations and industry standards. This involves conducting thorough inspections of all aspects of your operations, from receiving and storage to processing and packaging. By evaluating your processes and procedures against established guidelines, you can identify any non-compliance issues and take corrective action.

Internal Audits

Establishing an internal audit program is a crucial step towards ensuring food safety compliance in your facility. By conducting regular inspections, you can identify any potential gaps or areas for improvement in your food production process, allowing you to take proactive steps to address them.

Download our Internal Audit Checklist!

To establish an effective internal audit program, it is important to first define clear objectives and goals. This involves determining what you want to achieve through the audits, such as identifying potential risks, evaluating the effectiveness of your food safety measures, or ensuring compliance with regulatory requirements. By having a clear focus, you can tailor your audits to address specific areas of concern.

Third-Party Audits

When it comes to maintaining food safety compliance, hiring accredited auditors and preparing for audits and inspections are essential steps. These processes not only ensure that your facility is meeting regulatory requirements but also provide an opportunity to identify areas for improvement and enhance your food safety practices.

Learn more about external audits!

Hiring accredited auditors is crucial for conducting thorough and unbiased assessments of your facility's adherence to food safety regulations and industry standards. Accredited auditors have the necessary knowledge and expertise to evaluate your processes and procedures objectively. They are trained to identify potential risks, assess the effectiveness of your food safety measures, and ensure compliance with regulatory requirements.

Food safety compliance is crucial for consumer health and business success. Prioritizing food safety and adhering to regulations and industry standards builds trust with consumers and ensures the delivery of safe products. Implementing CleanTech® Automated Handwashing Stations enhances food safety practices and demonstrates a commitment to hygiene and customer well-being. By engaging in these practices, businesses protect their brand reputation and contribute to a safer food industry.

Take our product selection quiz to find out which automated hygiene system is right for your needs!