The Best Work Boots for Food Safety

Choosing Footwear that is Easily Cleaned and Sanitized

Not only is the hygiene method a key part of any footwear hygiene program, but the type of footwear used at your facility can also directly impact food safety. There are three main types of footwear that are used at food processing and packaging facilities:

|

|

|

|

Street Shoes |

"Captive" or "Zoned" Footwear A subcategory of plant shoes where footwear is designated to a certain zone in the plant |

Plant Shoes |

For employees, footwear is a very personal decision. Employees are usually on their feet most of the day so your facility’s choice in footwear is truly the difference between comfort or pain for your team. Because of this, many organizations choose to give employees freedom to purchase their own plant or street shoes to wear at the facility or may offer many options or types of footwear that may have different look, slip resistance or more importantly a different hygienic design. However, there are three main areas that companies or employees should take into account when choosing footwear to maintain food safety and hygiene excellence at their facility:

- Fit and Comfort

- Safety

- Hygienic Design

Fit and Comfort

Undoubtedly the most important aspect of footwear for your team is the fit and comfort of the boot or shoe they will be wearing. Employees need comfortable footwear with lots of cushion for standing during 8+ hour shifts. Footwear also needs to fit well, as footwear which is too tight or loose will cause blisters, discomfort and even pose a safety hazard. For comfort, also consider your organization’s production area. If it is a cold environment consider footwear with added insulation, for warm environments a more breathable material may be best.

Safety

Footwear is the foundation of your team’s safety throughout their workday as they move about your facility and the following should be considered to protect them:

Steel Toe

If heavy equipment is being used or they are carrying materials that could be dropped, steel toed footwear should be required to further protect employees that are handling or working around heavy machinery.

Tread Design or Material

Especially important in wet facilities, the bottom of the footwear should be made out of non-slip material that has good tread to ensure that employees do not slip and fall on wet surfaces.

Laces

Untied laces can easily cause a trip hazard or be caught in equipment, so some facilities may wish to avoid this safety risk altogether.

Hygienic Design

Protection, comfort and durability are typically the main considerations when first evaluating a footwear solution for your food production facility. However, many companies forget to consider boot design as a crucial factor when implementing a successful footwear hygiene program for food safety. Undoubtedly the most important aspect when choosing the type of footwear for use at your facility is its ability to be cleaned and sanitized. When choosing footwear which is best sanitized and determining what work boots to avoid in order to reduce the spread of pathogens in your food production facility there are several key aspects to consider:

Footwear Material

It is key that the material of the footwear can withstand heavy scrubbing and exposure to sanitizing chemicals. Some plastics and rubbers can degrade quickly due to sanitizer incompatibility and other materials like leather and canvas can actually absorb more pathogens, posing an even greater risk to food safety.

Footwear Height

When employing a footwear sanitation method like boot scrubbers at your facility, the height of employee’s footwear is key. Brushes can range from 3-9 inches in height so employees need to have an ankle high, mid-calf or a full boot that exceeds the height of brushes used.

Footwear Laces

Laces are common on most footwear but actually pose both a safety and contamination risk. If laces are not made out of a material that prevents saturation or absorption of fluids or chemicals, they can easily absorb and spread chemicals or pathogens throughout the facility. Untied laces also pose a slip hazard as well as a cross contamination hazard when employees re-tie them throughout the day.

Footwear Tread

Footwear that has shallow tread which is open to the sides of the footwear can be easily cleaned of debris and sanitized. Tight, closed tread increases the likelihood of impacted soils and prevents the footwear from being properly sanitized, posing a significant risk of contamination from outside debris or between production areas.

The best types of footwear for food safety are those with shallow, wide and open treads that allow for debris to be easily be removed from the bottom of the shoe. These types of treads also allow the boot to be easily sanitized when employees use an automatic boot scrubber and sanitizing station upon entering or leaving the production facility. For example, the best boots for food safety would have treads that look like the following:

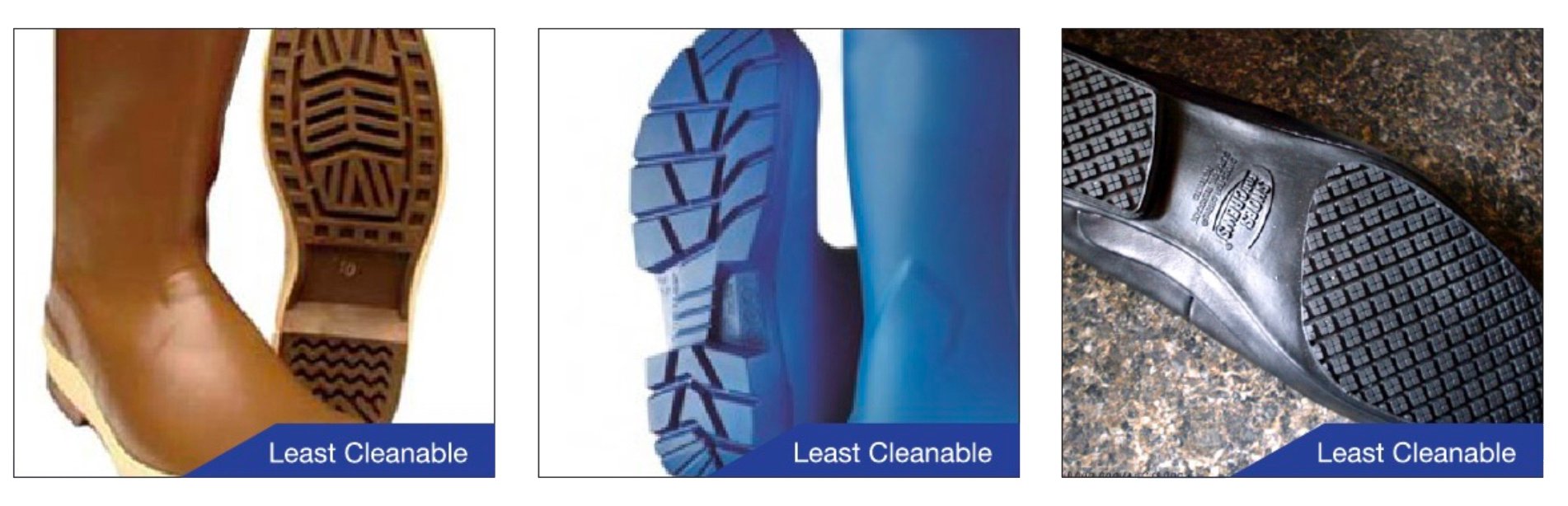

Unfortunately, some work boots can actually help spread deadly pathogens at your facility. The worst types of work boots for food safety are those with deep, tight and closed treads that tend to hold debris and pathogens. The following are examples of footwear that should be avoided to ensure effective sanitization when using a boot scrubber upon entering or leaving a production zone:

Download our Footwear Buying Guide for Footwear Cleaning and Sanitation Below!

Help your employees choose comfortable footwear that meets your facility's safety and hygiene requirements! Our footwear buying guide in both English and Spanish has detailed images that illustrate exactly what types of footwear tread employees should purchase to uphold hygiene standards and ensure food safety at your facility.

|

|

Download Footwear Buying Guide

If you have any questions about the footwear examples shown in this guide or implementing automatic boot scrubbers in your food production facility, contact our footwear hygiene experts at (800) 932 - 7707.