How Protein Manufacturers can Save Time in Meat Processing Facilities

Protein manufacturers in meat processing facilities are constantly seeking innovative solutions to enhance facility efficiency. Automated hand and footwear hygiene systems are a ground-breaking solution for meat packers to increase food safety compliance, enhance efficiency, and increase overall production. These systems have proven to revolutionize the way meat processing facilities maintain cleanliness and hygiene and, in turn, become an invaluable asset that saves time and streamlines operations.

Learn more about hygiene automation

Saving Time and Enhancing Efficiency In Meat Manufacturing

With automated systems, the hygiene cleaning process becomes effortless and hassle-free. Employees can simply place their hands or footwear into the automated system, and the system takes care of the rest (see the footwear sanitizing systems in action!) This not only saves time but also eliminates human error and reduces employee fatigue, enabling them to perform their tasks more efficiently.

Automated Hygiene Cuts Manual Handwashing in Half

Proper manual hand washing takes about 40 seconds, which is a long time in the fast paced meat processing industry. However it is essential that employees take the proper steps to ensuring food safety and hygiene. The solution to cutting handwashing time in half while still maintaining compliance is the CleanTech® automatic hand washing stations. The automatic hand wash cycle takes only 12 seconds, and with optional footwear enhancements, during those same 12 seconds employees can have their footwear sanitized as well.

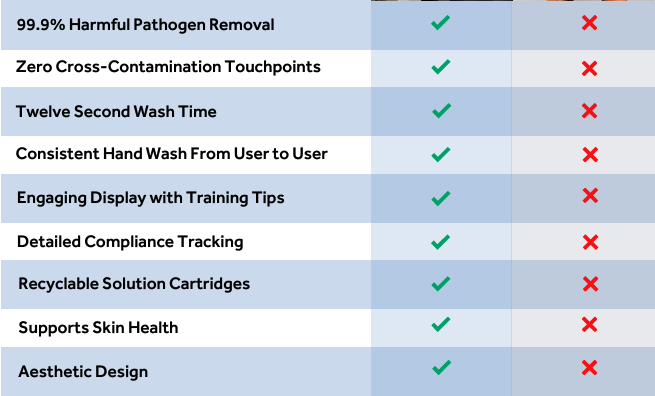

Check out this side by side comparison of manual handwashing and automated handwashing:

CLEANTECH WASH VS. MANUAL WASH

Download Full Infographic: A Comparison of Manual vs. Automated Handwashing

Learn more about hygiene equipment for meat packers

Reducing Risk of Cross Contamination for Protein Manufacturers with Simultaneous Hand and Footwear Hygiene

In addition to time-saving benefits, automated hygiene systems also play a crucial role in minimizing the risk of cross-contamination. Traditional cleaning methods often leave room for human error, which can lead to the spread of harmful bacteria or allergens. With automated, touch-free systems, human error is removed and the risk of cross-contamination is significantly reduced. With traditional hygiene systems employees take several steps to clean their hands and footwear, leading to increased opportunities for harmful pathogens to proliferate. This contamination risk is greatly reduced with CleanTech, where employees can preform hand and footwear cleaning at the same time.

Check out GMP Checklist for more tips on reducing risk and saving time

Meat packing facilities can save time by streamlining and automating hygiene procedures and processes and hygiene monitoring to ensure proper hygiene practices. With the integration of automated hygiene systems, protein manufacturers can stay ahead in the competitive meat processing industry while upholding the highest standards of cleanliness and hygiene.