3P's of Hygiene Stations for Food Safety - People, Place and Product

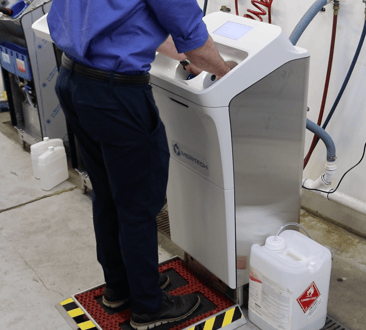

At Meritech, we are dedicated to collaborating with our customers to create a healthier and safer world by combating the spread of pathogens within their facilities. Through our expertise in hygiene education and consultation, we provide valuable insights through hygiene zone design consultations and facility site surveys. Whether conducted virtually or on-site, every visit to a facility revolves around three crucial aspects: the people, the place, and the product. We affectionately refer to these as the "3 P's of Hygiene Stations for Food Safety".

Hygiene Stations involve People:

When engaging with leaders at an organization to discuss the hygienic design of their food factories, we make it a priority to understand the number of individuals present at the facility and their daily activities. By gaining insight into their routines, interactions, and movement patterns within the facility, we can tailor the design of hygiene areas to best suit their needs. For example, if a production worker spends a significant amount of time in cold areas, we may recommend the implementation of supplementary hygiene zones to ensure their comfort throughout the day.

|

What is a Supplementary Hygiene Station? A supplementary hygiene station refers to an additional area within certain production zones that offers extra hygiene measures for workers. For instance, in cold environments, employees may be required to wear thermals as an added step in maintaining hygiene. This supplementary zone seamlessly integrates with the core hygiene zone process, ensuring that all team members are well-protected and comfortable throughout their workday. |

It is also important for us to have an understanding of the number of individuals passing through the core hygiene zone at any given time. This knowledge enables us to determine whether a smaller, more compact hygiene system would be more suitable or if a high-throughput hygiene station is necessary to ensure a smooth flow of people through the zone. Additionally, we need to consider the potential growth of the facility's employee population in the future to ensure our recommendations remain sustainable as the organization expands. By having an accurate count of the number of individuals, we can assess whether additional barriers or signage are required to guide larger groups of production team members through the zone, preventing them from bypassing crucial hygiene steps.

Download our Hygiene Zone eBook!

In addition to understanding how the employees of an organization maintain hygiene best practices, it is equally crucial for us to comprehend how visitors such as third-party contractors and auditors enter the facility and navigate through the hygiene zone. Do they require a separate hygiene zone near the entrance? Is it evident to visitors what steps they need to take? If they need to wear plant shoes, is there a designated area for them to conveniently change into and store their street shoes? By gaining insights into how both visitors and employees interact with the hygiene areas, we can design a hygiene zone that effectively minimizes cross-contamination and the spread of pathogens, while ensuring that everyone can move swiftly through the necessary hygiene steps.

Learn about our hygiene zone design consultations

Finding a Place for Hygiene Stations

When it comes to designing hygiene stations, we meticulously examine the facility and the designated areas, which we affectionately refer to as the "place." Our goal is to gain a comprehensive understanding of all the different spaces within the facility, ranging from the entrance and locker rooms to restrooms, break rooms, production areas, packing and shipping zones, as well as QA and QC areas. By comprehending the layout of the facility and observing how people navigate through it, we can conduct a thorough risk analysis of each area. If deemed necessary, we will strategically position satellite hygiene zones in the appropriate locations to prevent the infiltration of outside contaminants into production areas or the cross-contamination between allergen and ready-to-eat zones.

When it comes to designing hygiene stations, we meticulously examine the facility and the designated areas, which we affectionately refer to as the "place." Our goal is to gain a comprehensive understanding of all the different spaces within the facility, ranging from the entrance and locker rooms to restrooms, break rooms, production areas, packing and shipping zones, as well as QA and QC areas. By comprehending the layout of the facility and observing how people navigate through it, we can conduct a thorough risk analysis of each area. If deemed necessary, we will strategically position satellite hygiene zones in the appropriate locations to prevent the infiltration of outside contaminants into production areas or the cross-contamination between allergen and ready-to-eat zones.

|

What is a Satellite Hygiene Station? |

Hygiene Stations for Your Products

.png?width=294&height=294&name=10001%20(2).png) When conducting a site survey or hygiene zone design consultation, one of our primary considerations is the nature of the commercial goods being sold or manufactured. For instance, in production areas where wet goods like dairy are processed, we may recommend implementing a footwear hygiene method such as a boot scrubber or boot dip pan. It's essential to address the increased slip hazards in such environments and carefully choose a sanitation method that aligns with the facility's footwear requirements.

When conducting a site survey or hygiene zone design consultation, one of our primary considerations is the nature of the commercial goods being sold or manufactured. For instance, in production areas where wet goods like dairy are processed, we may recommend implementing a footwear hygiene method such as a boot scrubber or boot dip pan. It's essential to address the increased slip hazards in such environments and carefully choose a sanitation method that aligns with the facility's footwear requirements.

Take our product selection quiz to better understand your needs!

In a dry production environment for baked goods or medical cleanroom settings, it may not be suitable to use sanitation methods that involve excessive moisture. As a result, alternative options like shoe covers or low-moisture sanitation techniques for footwear should be considered. In ready-to-eat areas, additional steps may be needed to sanitize the gloves and footwear of employees after gloving. It's important to note that the type of product being produced directly influences the equipment we recommend for designing hygiene zones.

This brief overview highlights the central focus of our hygienic design consultations for food factories: the people, place, and product. At Meritech, we go beyond simply selling automated hygiene equipment. We establish true partnerships with our customers, ensuring that our equipment seamlessly integrates into their hygiene zones and meets their organization's specific needs.