Our innovative hand and footwear machine with built in hygiene monitoring stations are designed to ensure thorough and efficient hand and footwear hygiene moments, eliminating the risk of contamination and ensuring the safety and quality of frozen food products. With touchless technology with on screen, easy-to-follow directions CleanTech® Automated Handwashing and Footwear Stations made for frozen food manufacturers provide a time saving and convenient way for employees to maintain proper hygiene. By incorporating these into facilities, frozen food manufacturers can meet stringent FDA frozen food regulations industry regulations and prevent frozen food recalls.

| ChecK out our Full EVO Product Line | Learn more about CleanTech® Efficacy |

Check out our frozen food manufacturing equipment that makes frozen food production effective and worry-free from cross-contamination from human error and outside sources, including common frozen food recalls like Listeria and Salmonella. We've spent three decades developing and perfecting technology that blends engineering, science, and chemistry to automate the hygiene process, overcome human variability and provide a vastly more efficient and consistent hygiene event.

Read More about Essential Hygiene Practices for Frozen Food Manufacturing Regulations

.png)

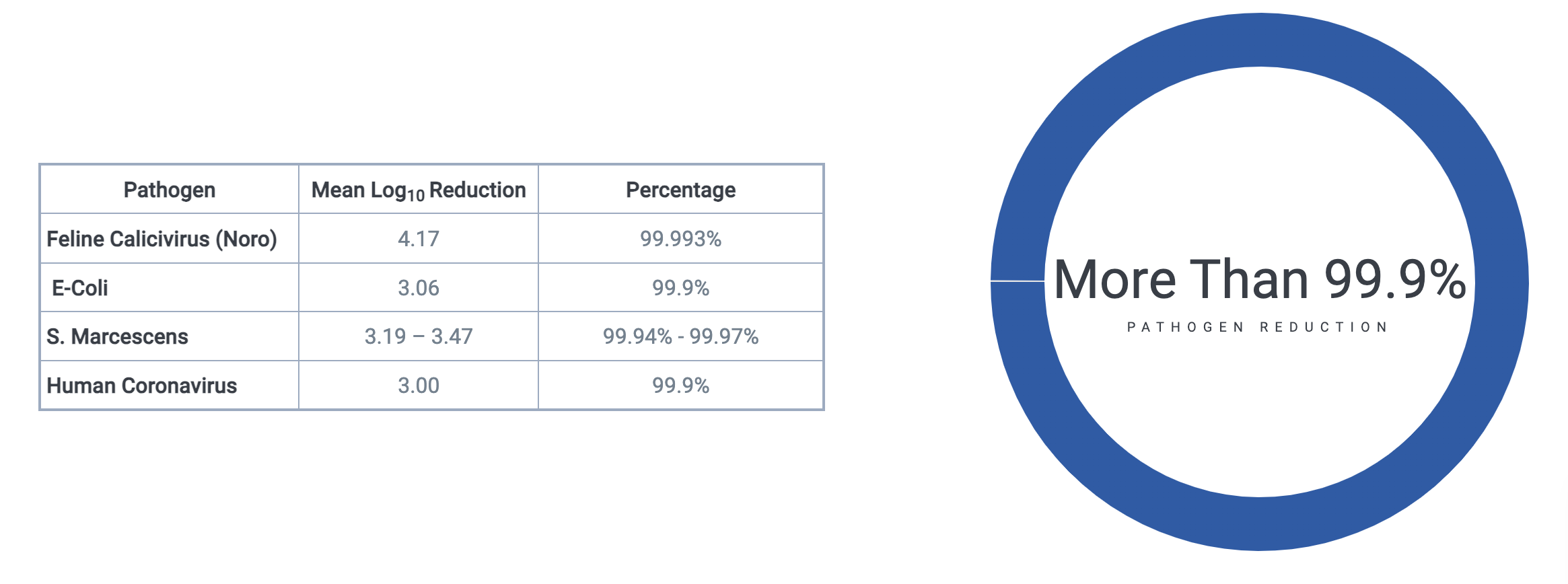

Remove more than 99.9% of pathogens from hands in a 12-second hand wash cycle.

Learn More →

Provide more effective footwear sanitation in the most demanding environments.

Learn More →.png)

Clean both employee hands & footwear in just 12 seconds for peace of mind.

Learn More →Fast and easy to use, regardless of age, language or skill level.

Proven in certified, independent laboratories to remove more than 99.9% of pathogens from hands.

Fast and easy for users, regardless of age, language or skill level to eliminate 99.9% of pathogens from their hands.

Designed for optimal pathogen reduction when used in Meritech automated hygiene systems.

Hygiene method with zero waste of water or chemical.

Automated hand and footwear hygiene stations are the ultimate secret weapon for frozen food manufacturers to ensure top-notch food safety standards and hygiene compliance. Traditional hygiene methods can struggle with compliance and employee hygiene monitoring. Without automation, these traditional methods lead to human error and variability which can result in poor hygiene practices and the spread of harmful pathogens. Our hand and footwear hygiene stations for frozen food manufacturers are designed to revolutionize your frozen manufacturing process to ensure top-notch hygiene standards, reduce risk, and prevent frozen food recalls.

Learn More about Why Hygiene Automation Works

Not only do Meritech’s automated hygiene solutions reduce the risk of cross-contamination and pathogen spread they:

By incorporating these stations into the frozen food production process, frozen food manufacturers can significantly increase compliance to reduce the risk of cross-contamination, including salmonella and listeria in frozen foods. When you implement our hand and footwear stations, you're not just meeting compliance requirements; you're showcasing your commitment to excellence.

Read more about Essential Hygiene Practices for Frozen Food Manufacturing Regulations

Get the ultimate peace of mind with our hand and footwear hygiene stations that are made for frozen food manufactures and built to reduce frozen food recalls in compliance with FDA frozen food regulations and USDA frozen meat guidelines. We have conducted over 50 third-party efficacy studies in certified independent laboratories to ensure the effectiveness of our automated hygiene systems. These laboratories specialize in topical antimicrobials and the science of hands, and they use the ASTM hand hygiene testing mandated by the FDA. This testing method, known as the “Glove Juice Test Methodology,” is the standard in the United States for validating hand hygiene effectiveness. The results speak for themselves: our CleanTech® automated hygiene systems have been clinically validated to remove more than 99.9% of pathogens from hands during each 12-second cycle.

We leave no stone unturned in ensuring that hand and footwear washing machines are validated to exceed FDA frozen food regulations and USDA frozen meat guidelines. Implement automated frozen food production hygiene equipment that is clinically validated to remove more than 99.9% of pathogens from hands during each 12-second cycle. Your frozen food manufacturing facility's reputation and your customers' safety are our top priority.

Consistency and ease are key in effective frozen food equipment. Frozen food manufacturers needsimple-to-use hand and footwear hygiene frozen food manufacturing equipment and automated to reduce human error to make it consistently effective for all users to ensure that the wash is adequate. Automated hygiene equipment is the ultimate game-changer in maintaining food safety regulations and a hygienic environment for all users.

At Meritech, our innovative approach eliminates the variability that can occur in manual systems and manual handwashing, guaranteeing that each and every hygiene moment is a perfect wash. Our hand and footwear frozen food equipment with built in hand and footwear hygiene monitoring is designed to ensure a swift and hassle-free wash and reduce the risk of cross-contamination by utilizing sensors, timing, and touchless operation.

Learn More about CleanTech® 12 Seconds to Clean

Learn More about how Technology Helps with Hygiene

By investing in CleanTech® automated hand and footwear stations, frozen food manufacturers can ensure a clean and efficient production process, ultimately benefiting both the frozen food production facility and the customers it serves.

Read More about Essential Hygiene Practices for Frozen Food Manufacturing Regulations

Keep your frozen food manufacturing facility hygienic and keep your frozen food customer safe with our hand and footwear hygiene stations with equally formulated solutions that are made to prevent frozen food recalls. We have uniquely formulated hygiene solutions are designed to ensure the highest standards of hygiene, skin health, and food safety throughout your frozen food production process. Meritech's refillable solution cartridges are specifically designed to work with our automated hygiene system to ensure the removal of 99.9% of pathogens during each hand washing cycle and ensure the perfect hand wash in your frozen food manufacturing facility.

Frozen food manufacturers can streamline frozen food production, reduce downtime, and increase overall output of frozen food facilities with our technology and solutions. Plus, not only are these unique solutions designed for optimal pathogen reduction, but they also improve skin health, which is important for the prevention of pathogens. They are alcohol-free, fragrance-free, triclosan-free, dye-free, biodegradable and kosher.

Our hygiene equipment is designed with efficiency in mind, and we're proud to be creating eco-friendly and sustainable hand and footwear hygiene equipment. Meritech CleanTech® systems revolutionize the concept of sustainable and eco-friendly hygiene for frozen food manufacturing. These automated handwashing stations are sustainability designed:

With Meritech CleanTech® systems, you can ensure cleanliness and hygiene in your frozen food production facility without compromising your commitment to sustainability.

Since Nutraceutical products do not require FDA approval, being able to confidently assure and inform your consumers that your supplement processing facility has proper hygiene and food safety management systems in place. With Meritech's fully automated hygiene system, you can always be confident in your nutraceutical plant's hygiene compliance. By prioritizing hygiene and safety in nutraceutical processing, your consumers will feel more comfortable with your nutraceutical product and you will be able to uphold the integrity of your supplement brand.

A good manual handwash is effective at reducing hand bacteria counts, no doubt. However, the manual handwash method cannot be guaranteed to be consistent from person to person and day-to-day, otherwise this would be a good alternative. Manual handwashing is inherently variable. Important aspects of the handwash, such as amount of soap, amount of water, coverage of the hand (fingernails, fingertips, between the fingers, wrist, etc.), and duration of the wash vary from wash to wash. By automating the process, these aspects are closely controlled and each person gets a high-quality handwash independent of the human variability factor. If you have had no problems in the past, then statistically you are overdue for a problem. CleanTech will standardize each hand wash and guarantee clean hands. Meritech has performed an independent study which demonstrates that our technology-based approach to hand hygiene, with a 12 second cycle, is equivalent to a full 1 minute wash (30 seconds of lathering, 30 seconds of rinsing).

Because of the high risk of cross contamination! In a study by BioScience Laboratories that tested randomly selected vinyl food grade gloves, 80 percent were found to have pre-existing punctures or tears. In addition, the use of gloves creates the perfect environment for the breeding colonies of pathogens on the hands. When handwashing was performed prior to gloving, no significant microbial growth was observed. In another study, hands that were initially inoculated with E. coli before donning gloves were determined to have significant counts on the outside surface of the gloves after use – this is known as cross contamination and it is why there are many industries that actually discourage glove use. For those companies that do use gloves, the CDC recommends washing before gloving due to the rapid growth of bacteria on gloved hands, and due to the risk of punctures and tears during use. When hands are washed effectively prior to wearing gloves, the risk of cross contamination is reduced but the key is that the manual wash needs to be effective. Only a Meritech CleanTech system can guarantee an effective wash prior to gloving.

It is critical to implement and educate hygiene standards throughout your entire nutraceutical manufacturing facility and throughout the entire nutraceutical and supplement production process. It is also key to have the right hygiene equipment available for your nutraceutical plant workers. The right equipment is easy-to-use and fast, like Meritech's handwashing and footwear hyiegen systems. The digital screen plays the simple instructions each time the machine is used and is only a 12 second cycle, making it easy to train new employees and making it a very quick process.

Alcohol gel is not the answer to the problem of poor hand hygiene and should be used ONLY when manual washing or a Meritech system is not readily available (this is the position of the FDA)! Instant hand sanitizers are not an acceptable method for handwashing in any food applications (production or food service). The reason is that hand sanitizers are rarely used correctly, and if they are, the contact time should be 20 to 30 seconds total, to be effective against many pathogens. Sanitizers are NOT healthy for the skin and actually damage the skin to the point it is easier for many pathogens to colonize in the cracks of dried and dead skin. Most importantly, alcohol gel sanitizers are not effective against many pathogens and the use of alcohol gel can actually promote the spread of disease by creating a false sense of security and discouraging effective handwashing. Norovirus on cruise lines are a great example – the CDC has clearly stated that alcohol gel does not kill or remove norovirus and cruise lines are being required to encourage more regular or CleanTech automated handwashing. When instant hand sanitizers are used in ANY application, people are misled to believe that they are cleaning their hands; therefore they lessen their trips to a sink with soap and water. This false sense of security actually increases cross contamination and infection rates.

Please refer to each model’s spec sheet for details. All systems require the same plumbing as a standard sink; hot & cold water supply and a drain, and 110V power outlet. Note that our systems do not heat the water. The hot water is supplied by the facility and then the system will automatically blend the hot and cold to about 105ºF. If there is a hot water supply problem, a booster heater is recommended and Meritech engineers can help you with specifications for a booster heater.

CleanTech shines in three areas:

Fill out the form below and someone will be in touch with you shortly.

Designed to help you create a culture of hygiene excellence at your organization, the Employee Hygiene Toolbox includes six modules covering everything from hand hygiene best practices to hygiene zone design.