Preventing Cross Contamination in Food Production

Cross contamination in food is a constant risk in food processing facilities. Moving from one area of the facility to another without taking the proper personal hygiene measures can result in contaminated product. The highest risk comes from transitioning from areas where raw food is being processed to zones where ready-to-eat (RTE) food is being finished. Food processing facilities need to take every measure possible to prevent cross contamination and protect their customers.

Understanding Hygienic Zoning is the Key Preventing Cross Contamination in Food Production

Hygienic zoning is a facility design approach that segments a production area into specific zones according to contamination risk. Its goal is to prevent cross-contamination by keeping high-risk food areas separate from lower-risk ones. This involves controlling the movement of people, materials, and airflow to safeguard the final product from potential hazards such as bacteria, allergens, or foreign substances. Essentially, it is a strategy to reduce contamination risk by managing the flow within a facility based on the food safety risk level in each area.

Zone 1 and 2: Highest Risk of Contamination

Zones 1 and 2 are the areas where food products are most susceptible to contamination, as equipment comes into direct contact with the food. Zone 1, in particular, presents the greatest risk for pathogen contamination. Zone 1 includes:

- Conveyor belts

- Rollers

- Brushes

- Tabletops where produce is handled

- Workers' hands

- Reusable plastic containers and storage bins

- Sinks

In these areas, it is crucial to adhere to personal hygiene best practices, as the risk of contamination is at its highest. Handwashing is a necessary practices before employees or visitors enter these zones.

Learn more about how Automated Hygiene can reduce the risk of cross contamination

Zone 3 and 4: Lower Risk Zones of Contamination

Zones 3 and 4 are areas with a lower risk of contamination. In these zones, food products do not come into direct contact, but employees may still pick up harmful pathogens on their hands and footwear.

Maintaining proper personal hygiene is essential when moving from zones 3 and 4 to zones 1 and 2, where food contact takes place. If an employee or visitor enters the main food production areas from zone 3 or zone 4, cross contamination from the facility to the food can occur, endangering your customers.

Learn how Automated Hygiene can be implemented in every zone in your facility

Transition Zones: Moving from Low Risk Areas to High Risk Areas

Transition zones are crucial areas where employees and visitors move from low-risk zones (zones 3 and 4) to high-risk zones (zones 1 and 2). In these zones, it is vital for everyone to practice proper personal hygiene to minimize the risk of cross contamination in food processing. These areas should be equipped with handwashing sinks or stations and footwear sanitation systems. If there is a considerable amount of debris on the floor, a boot scrubber may also be necessary.

Interested in learning more about hygienic zoning and how Automated Hygiene can assist with preventing cross contamination?

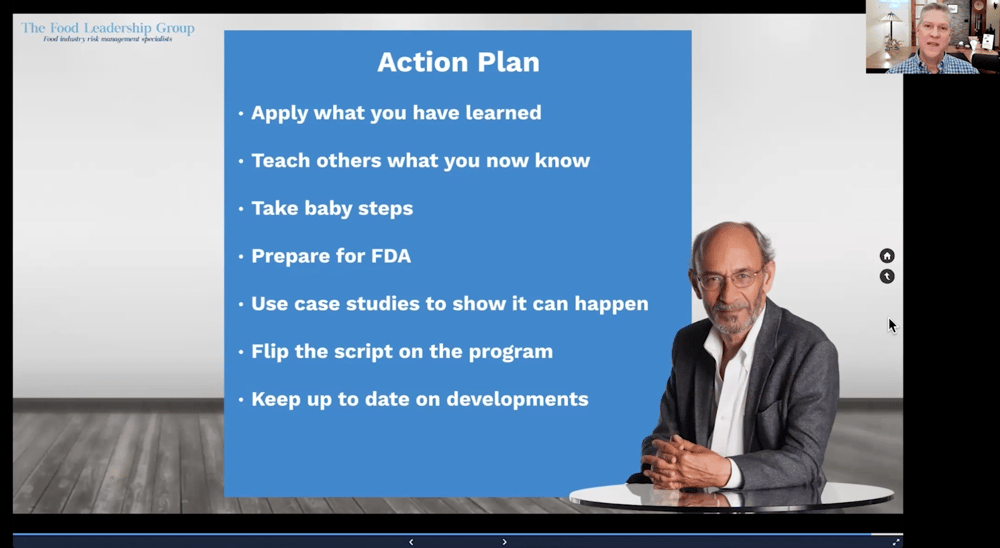

Meritech and Bryan Armentrout, the Founder of the Food Leadership Group, partnered on an insightful webinar about proactive and reactive food safety with a focus on properly the addressing hygiene zones to reduce risk of cross contamination.