The Wash Podcast: Creating a Hygiene Culture for Food Safety

Welcome to The Wash, your trusted resource for the latest and greatest in public health and hygiene, where we will tackle topics like hand hygiene, best practices in footwear sanitization, creating an employee hygiene program, and more!

On today’s episode, we invite Meritech CTO Paul Barnhill to help listeners understand the importance of creating a hygiene culture in food processing. Mr. Barnhill goes into detail explaining what a hygiene culture is, how to begin creating one at your facility and explains why this is key part of overcoming the greatest source of risk in achieving proper hygiene: the variability of human behavior

You can listen to the podcast using the media player or read the podcast transcript below:

Podcast Transcript: The Importance of Creating a Hygiene Culture in Food Processing

Abigail Owiesny: Hello, and thank you for joining us for another episode of the wash, your trusted resource for the latest and greatest in public health and hygiene. This podcast is brought to you by Meritech, the leader in automated hygiene technology. I'm your host, Abigail Owiesny, and joining me today is Paul Barnhill, Chief Technology Officer and head engineer here at Meritech. Paul, thanks for joining us today!

Paul Barnhill: Thanks, I'm glad to be here!

Abigail Owiesny: In our last two episodes, we discussed hand and footwear hygiene in food processing. Today, we're going to discuss the important role that creating a hygiene culture plays in ensuring food safety. So let's get started!

Paul in this industry we talk about a lot of different potential sources of contamination that can affect food safety. What would you say is the largest source of contamination at any food processing facility?

Paul Barnhill: What an absolute great question. I think one of the biggest things, without a doubt in my mind is human behavior is the largest source of contamination. It's really bringing across those risks. You know we put a lot of processes and procedures in place, but one of the things that we lack sometimes within those, you know, which are really just fundamental processes that we need to follow is really the human behavior, the aspects of how a person goes through about their day of work. I think that's really, really key. You know, when a person or employees and counting that job: how many different surfaces do they touch? Even, touching themselves, touching their face, touching their hair. How many times does somebody touch their nose? Those kinds of studies have been done and the numbers are staggering.

But I think you have to look at that aspect of the human, and much different than that is when we look at our staff of: What type of people do we have? Do we have full time employees? Are we employing temporary staff and using those temporary staff to really carry out the day? Or are we using seasonal workers? Do they have those same cultures, those hygienes that we need? Or like all food manufacturing, we're dealing with a diverse work culture, many different languages, I believe one of the numbers that I saw the other day was 32 different dialects were being spoken in a single plant. That is challenging for any management source.

Abigail Owiesny: So how do you overcome that human behavior aspect to reduce contamination at a plant?

Paul Barnhill: You know, we, we produce a lot of procedures and so forth. And again, these are all mechanical items for compliance, but to me it's about creating a hygiene culture. I think the most important aspect of doing that is creating what is called the culture of hygiene excellence. It's really a way of getting everybody to be on what I call a flat line of leadership.

So you know, you have some aspects of top-down leadership, and then you have the bottom-up leadership models. This is really so much different when it comes to a hygiene culture. It's really, everybody's on the same flat line from your executive management to your middle management, to your team leaders to your team members are really all on the same flat line of expected culture that they are going to be held to when it comes to food safety and hygiene.

It's really more mental than it is really physical. It's really about making sure that everybody understands: Why is it that we want to do this? What is the importance of creating a hygiene culture that is so, so key? One of those aspects is what's called the food safety committee. I actually want to do a shout out really quickly to Joyce Watford's article in Food Safety Magazine: Leveraging Food Safety: The Cross-Functional Food Safety Committee. And she touched on this a little bit, she touched on the culture of hygiene. She really focused on that, and what that means when it comes to a food safety committee.

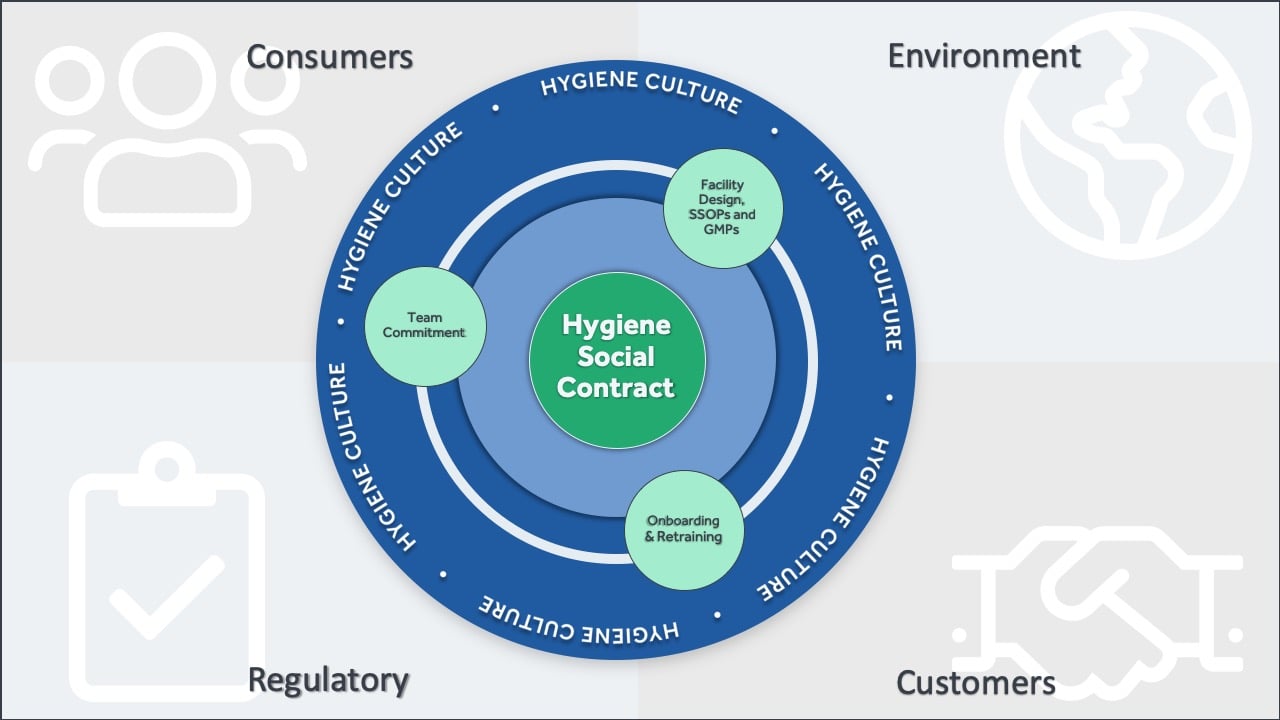

But what Meritech is doing is really focusing on that culture of hygiene, of how do we create that, that can play into all aspects of food safety. And at the heart of this is what we call an employee hygiene contract. And what that does is it basically holds everybody to the same set of guidelines. It's a very simple one page document in multiple languages, so you're able to understand exactly what is it the core that we need to do to maintain a hygiene culture, and it comes with that hygiene social contract.

Abigail Owiesny: Paul, that all sounds very official. What exactly is a hygiene social contract?

Paul Barnhill: Everybody kind of gets a little "Oh, it's a contract. Oh, I'm worried about a contract". It really isn't, contracts like this, social contracts, have been used in business classrooms for many, many years. Even if you think about that, our own Constitution in the United States is really basically a social contract.

So it's really just merely a set of guides that establishes the rules of behavior and expectations all employees are held to but the sole focus, on our part, is around hygiene. For this process to work fully, it must include all members of the company, regardless of their position, and each must sign and agree to follow the hygiene aspects outlined in the contract. It's a very simple, easy guide that puts everybody again on that flat line.

Abigail Owiesny: So I love this idea to have a hygiene social contract, but I feel like with a new employee, if you had them read and agree and sign this contract, it's really only one step of what needs to be a much larger onboarding process. Is that right?

Paul Barnhill: Absolutely, this is only one tool within this toolbox! This is really just a piece, but again, this is pinnacle piece. Everything focuses around it. So when you create a hygiene culture, you really are creating a giant circle of culture, and then everything plays into it.

And so the hygiene social contract is one you really have to talk about your hygiene and importance in your facility. People need to understand "why is it that we need to perform hygiene?" You need to review and sign the employee social contract for that, for the introduction of it. You have to train your people on the SLPs. They have to understand, the risks associated with the human behaviors, the touchpoints. You need to have good training videos to train them. With each individual that may be different, each plant may be different depending on what you do and how you interact.

I think one of the things I mentioned many years ago , is what are called the three "P's". The "People" the "Place" and the "Product" and how all of these things tie together when it comes to a hygiene culture. You have to go over footwear, donning procedures, hand hygiene, do I use a sanitizer? Do I not? Do I use a bootie? Do I scrub the shoes? and so forth.

All this is to encompass employees, but also has to encompass new employees, existing employees, temporary employees, and then retraining of all those employees. So every aspect of this has to be done all the time. And one of the big things about this, that I think is really key on that onboarding process is creating a hygiene mentor. You know , we have a team leader that leads the people and then you have your team members. But what I advocate for is a hygiene mentor. And that mentor is there to actually help and guide and train that person on the proper hygiene. Keep in mind, that human behavior is the biggest risk factor when it comes to food safety. So with this mentor, its to really kind of guide this through.

Abigail Owiesny: All right, Paul, so you onboard and train a new employee on hygiene. They have their mentor. What are some of the ongoing things that should happen at a facility to maintain the hygiene culture?

Paul Barnhill: It really is about the facility design, the layout. You know, operational flow is really key so that you make sure that people are coming in the facility the right way that they need to go. That you're not having missteps , when it comes to food safety or to hygiene or could somebody accidentally, when you have a backup of people circumvent the process - these are all risk factors.

You have to monitor hygiene. You have to monitor your reentry points if I'm able to go outside from here can I come back? So it really is about the facility's design, the layout, the operational flow. That's really key. You have to talk about all your different aspects of: how do we get into the facility? What is it that we have for our clothes that we show up for work in? What do we, what do we have for outerwear? Is the outerwear that we have: Deteriorating? Is it in good shape? Is it clean? Do you have pockets above the waist? Do you have buttons? These are all concerns.

Then one of the things I think is really key when it comes to hygiene, especially when it comes to hand hygiene or footwear hygiene or so forth during team huddles, is making sure that people are discussing hygiene. Talk about it. Don't just leave it till you have a problem. Discuss it all the time, bring it up, make new and creative ways of discussing the hygiene: "Hey, make sure that you're going through your hand hygiene. Make sure you're following the process and procedures." With those subtle reminders, is always keeping aware. Again, that plays back to that mental part of creating the hygiene culture.

It's, you know, obviously the mechanical parts of this are making sure that your SSOP's, or your GMP's are up to snuff. You know, that's the part about being compliant. Are we being compliant with the way the regulations are written? And are we following those processes? But it's also about creating, CAPA's which are your Corrective And Preventive Actions, to make sure that we're doing things correctly. Visual training materials are key right now in every food manufacturing business. If you're not using visual training materials, you're missing out on a lot of individuals understanding exactly; again, due to the diverse work culture.

And it's really about creating a committee that's focused, but it's about creating that culture. If you're not creating that food safety culture, if you're not creating that hygiene culture, you're really are putting your people, your place, and your products at risk.

Abigail Owiesny: Paul, thank you so much for sharing your time and expertise with us today. It was great to explore the topic of creating a hygiene culture with you!

Paul Barnhill: Thank you, I always enjoy it!

This podcast is brought to you by Meritech, the leader in automated employee hygiene. Meritech offers a complete line of fully-automated hygiene equipment that provides the only clinically-validated, technology-based approach to human hygiene in the world. Meritech’s line of CleanTech® Automated Handwashing Stations perform a fully-automated 12-second hand wash, sanitize and rinse cycle, removing over 99.9% of dangerous pathogens while wasting zero water or solution. Meritech delivers employee hygiene, contamination control, and infection prevention programs within a wide variety of markets, including food production, food service, cleanroom, healthcare, medical, theme parks, and cruise lines. For more information call 303-790-4670.