How Technology Improves Hand Hygiene Compliance for Food Safety

We all know how important it is to maintain good hand hygiene, especially in places like food processing facilities and restaurants. Maintaining compliance with hygiene standards can be a daunting task, especially when relying on manual handwashing methods that are prone to inconsistency. Often the solution is additional training or policing the behavior, two methods that cost additional time and resources. Fortunately, technology can improve hand hygiene compliance and make training effortless.

We've embraced technology and innovation everywhere...why not with hand washing?

Ignaz Semmelweis, a Hungarian doctor working in Vienna General Hospital, is known as the father of hand hygiene recognizing its importance in 1846. Hand washing was further promoted by Florence Nightingale several years later who implemented handwashing and other hygiene practices in the war hospital in which she worked. However, it wasn't until the 1980s, when several foodborne outbreaks and healthcare-associated infections led to public concern, causing the United States Centers for Disease Control and Prevention to identify hand hygiene as an important way to prevent the spread of infection and publish the first nationally endorsed hand hygiene guidelines.

Despite the numerous technological advancements we've made in virtually every aspect of our lives, we still stick to the same manual hand washing methods and guidelines that were introduced decades ago by Semmelweis and the CDC. This begs the question: why are we not embracing innovative solutions to improve hand hygiene? The traditional methods of manual hand washing have continually proven to be ineffective, as evidenced by the numerous pandemics and foodborne outbreaks that have occured. It's time to embrace technology and revolutionize hand hygiene practices to keep ourselves and others safe.

The best technology for improving hand hygiene compliance for food safety

Did you know?Even CleanTech® automated handwashing has evolved over the years! Meritech was founded in 1986 and our stations have advanced a lot since then to bring you the perfect hand wash. Just look at the concept image from the 1980s below vs our latest EVO Automated Handwashing Technology .png?width=611&height=344&name=Untitled%20design%20(6).png) |

Companies improve hand hygiene compliance for food safety by embracing handwashing technology

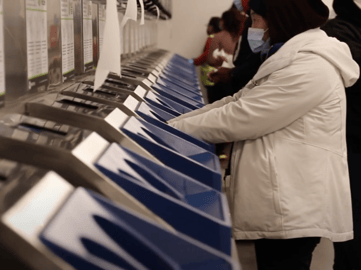

Among the companies we've collaborated with to enhance hand hygiene compliance for food safety by deploying automated hygiene technology at their facility is HelloFresh. HelloFresh has always been at the forefront of innovation in their operations and it's no surprise that they have embraced the latest hygiene technology.

HelloFresh was facing a challenge with their old employee hygiene methods, which required constant supervision from food safety supervisors to ensure proper handwashing techniques were being followed. With a large number of employees working in their production areas and high foot traffic, monitoring every employee became an overwhelming task. That's where CleanTech® came in, providing a solution that eliminated the need for constant policing and ensured every employee received a proper hand wash every time.

HelloFresh was facing a challenge with their old employee hygiene methods, which required constant supervision from food safety supervisors to ensure proper handwashing techniques were being followed. With a large number of employees working in their production areas and high foot traffic, monitoring every employee became an overwhelming task. That's where CleanTech® came in, providing a solution that eliminated the need for constant policing and ensured every employee received a proper hand wash every time.

With the addition of CleanTech®Automated Handwashing Stations that replaced the sink basins, it was no longer necessary to monitor proper handwashing techniques since every hand wash is done the same for every employee who places their hands in the CleanTech® system. This provided HelloFresh with peace of mind for their hygiene zones and allowed them to easily train new employees on handwashing with the systems.

“You stick your hands in and it does all the work for you. The easier you make it, the more fun it is, your employees are going to follow that. That’s been really great for us.”

Ahsha Abu-Ali, Associate Director of Food Safety at HelloFresh

Throughout history, technology has been utilized to enhance safety, streamline processes, and increase efficiency in various aspects of our lives. It's time to apply this same ideology to hand hygiene to ensure the safety of employees and consumers. By embracing innovative solutions like CleanTech® EVO Automated Handwashing Technology, we can revolutionize the way we approach hand hygiene, prevent the spread of dangerous pathogens and make the world a healthier and safer place.